Carter AFB Metering Rods & Jets

I get a lot of questions about the AFB and how the jets and metering rods are related, so here we go.

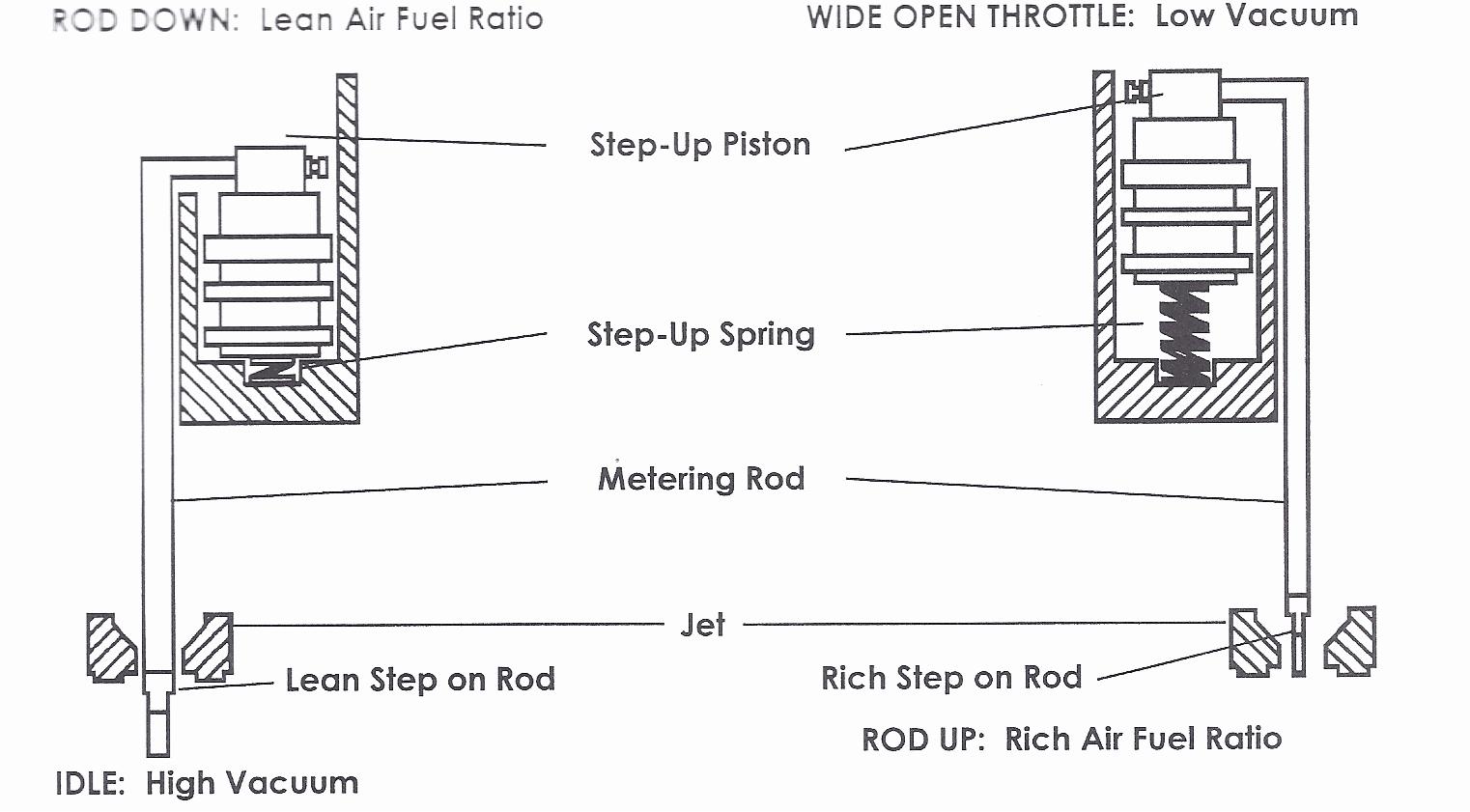

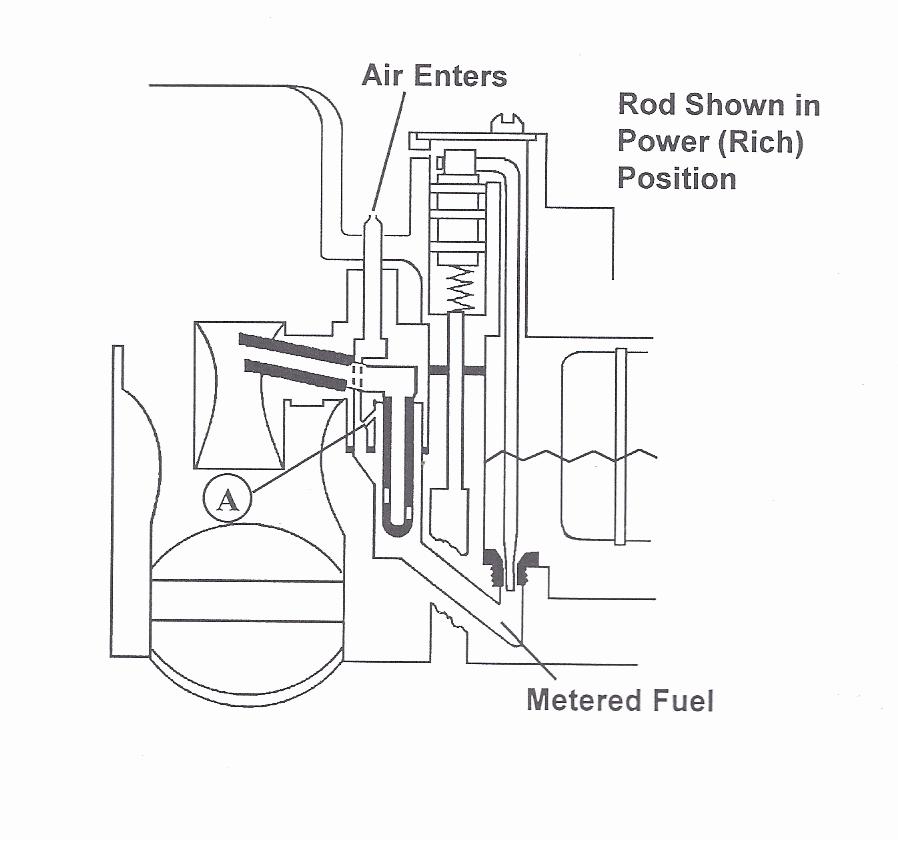

In the illustration A indicates a bleed which prevents a rich condition and bog when the high speed circuit is reinitiated after deceleration.The wrong step up piston spring or using a spring that has been stretched out of shape can eratic carburetor behavior at low and high speeds. We sell the metering springs in full sets, which allows you to experiement. For the best running conditions at both low and high speeds, use the lightest spring that you can and still get the best performance from your carburetor. A couple of other things to look for when you aren’t getting the performance you expect is a clogged air bleed or main vent tube, which would cause a rich condition. A float with an incorrect setting will also cause poor performance at higher speeds.

Buy your metering rod springs here.