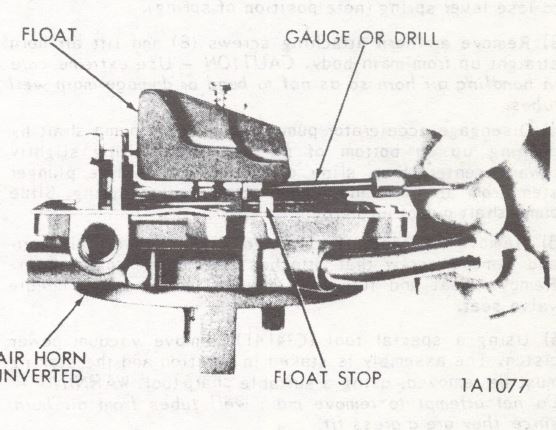

How to Set the Float Level

When measuring the float setting, be sure that weight of float only is forcing needle & seat, otherwise damage to the needle can occur.

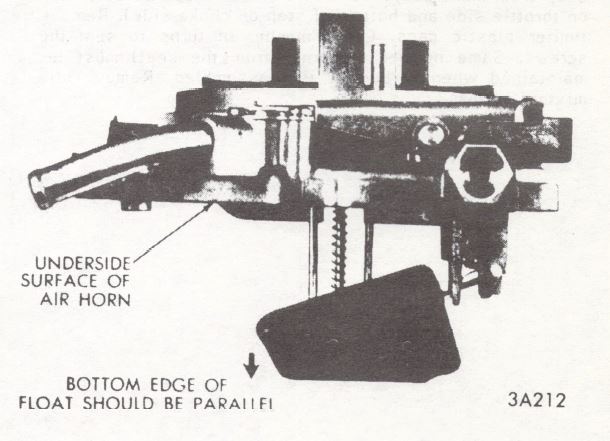

Float Drop

With air horn in normal position bottom edge of float should be parallel to underside surface of air horn. Bend tang on float arm to obtain correct adjustment.

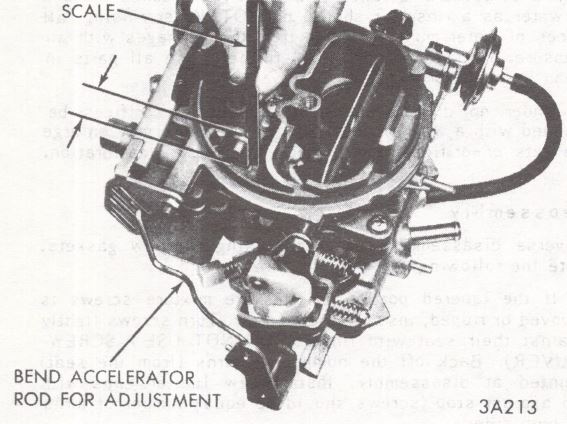

Accelerator Pump Adjustment

Seat throttle valves in bores by backing off curb idle speed screw and opening choke valve. Pump connector rod must be installed in correct slot of accelerator pump rocker arm. Measure distance between top of air horn and end of plunger shaft. If adjustment is required, bend pump operating rod, at loop of rod, until correct setting has been obtained.