Float Alignment

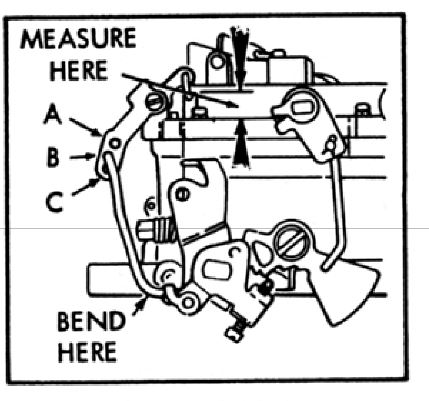

Look down the edge of the float to make sure it is parallel with the edge of the float bowl top.To adjust, pull the end of the float one way or the other to make it parallel. Support the back of the float with your thumb as shown in the illustration.

Make sure the float doesn’t bind when moving it up and down.

Measure the float level with the float bowl gasket installed and the needle & seat installed. The gauge illustration is not available. Instead measure with a metal ruler. Use the setting printed in your carburetor kit instruction sheet.

Adjust by bending the float at the hinge as shown in the illustration.

NOTE: Do not put any pressure on the needle when adjusting the float. Any pressure can damage the tip, causing the needle & seat to leak.

The float drop is important because when it drops the needle pulls out of the seat allowing fuel to enter.

Adjust by bending the tang in back of the float hinge. This tang will hit the seat stopping the drop.

The float drop setting is in your carburetor kit instruction sheet, but for the most part it can be any size, as long as the needle doesn’t fall out, or cocks to one side. It also needs to drop enough to allow the needle to move out of the seat.

NOTE: Do not put any pressure on the needle. Doing so will damage the needle and you will get too much fuel into the bowl.

Pump Adjust

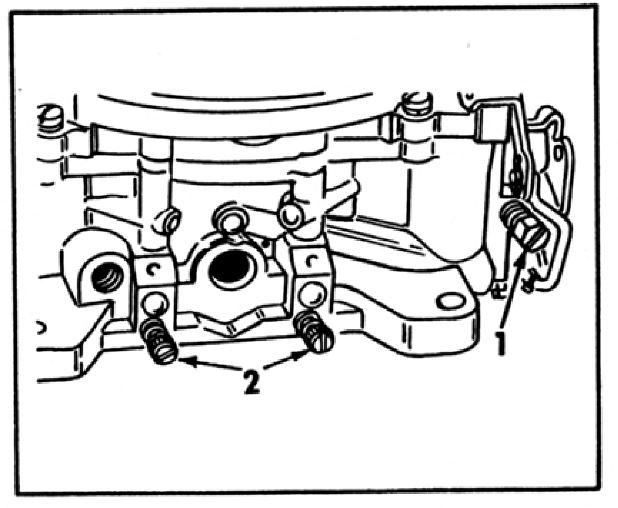

Adjust Idle Mixture

Adjust stop screw (1) to crack valve slightly. Start engine. Adjust mixture screw (2) until engine idles smoothly. Readjust stop screw (1) to idle engine at approximately 450 RPM; then readjust mixture screw (2). High Performance idles at about 500 RPM.