BBD Accelerator Pump Assembly

Gas is flooding over the top.

Bottom line is that you are getting too much fuel in the float bowl.

Can be caused by the following (could be other causes not mentioned).

- Fuel pump pressure too high. Should be around 4-5, but check your motors manual for the exact pressure. New pumps are especially suspect.

- Needle damaged. The Viton tip can easily be damaged when installing. Don’t put any pressure on it.

- Test the needle & seat for leaks.

- Dirt in the seat causing the needle not to seal.

- Float leaking causing it to be too heavy. Heat up a pan of water and dunk the float. You should not see any bubbles.

- Make sure the floats are not rubbing the sides of the carburetor. They should be centered.

- Float has a retainer and when the top is on the carburetor the retainer is pressed down and that holds the float in place.

Gas Boils Out After Turning Engine Off

This is called percolation. The float bowl top vent is used to relieve the fuel vapors from the float bowl, otherwise the vapors enter the carburetor bore causing a rich condition. Hard starting can also occur. The vent should open when the throttle is at idle position.

This is not the only reason for percolation. The engine may be getting too hot, gas has a lower boiling point that it used to. Try different brands and grades of fuel. Make sure fuel lines are away from the manifold. Run a 2nd line back to the gas tank which will help cool the gas. Add an electric fuel pump and use just before starting to re-fill the fuel bowl.

Coughs, or hesitates when stepping on the gas

Accelerator pump service may be in order if the engine stalls or hesitates accelerating at low speeds. A good tip to remember is that if an engine at operating temperature coughs through the carburetor and the air horn appears sooty, the mixture is probably too lean. An over-rich mixture could cause the engine to lag or hesitate but it normally won’t cough.

Surge & Stumble 1968-71 383 With Carter 1 1/2″ BBD Carburetor

This can be caused by a warped air horn (bowl cover), which causes an air leak between the fuel bowl and venturi section.

Hard Starting

- Be sure the electrical system is up to par, especially the plugs.

- Heat from the engine may be causing the carburetor to percolate (gas boils). This allows too much gas into the intake manifold and until this is cleared out, the engine will not start.

Rough Idle

Carburetor numbers: 4955S, 4956S, 6025S, 6026S

Rough idle due to over rich condition on the subject units. Should such condition occur install a plug as show in the illustration. The plug should be driven to mating surface only.

Cold Sags, Die Outs & Pop Backs

For all drivability complaints, check all vacuum hoses to make sure they are properly connected. A disconnected hose can allow air leaks which give lean mixture as well as problems of improper action of the component operated by the hose. Also ignition contact point gap and ignition timing should be checked on al drivability complaints. Engine sags, die outs and pop back during warm up are usually caused by retarded ignition timing, improper carburetor choke vacuum kick adjustment, cam index setting, fast idle speed, and mixture setting.

Retarded basic ignition timing causes pop back during starting. Adjust to specification on vehicle emission control label +_ 2 1/2 deg for best engine operation.

On engines equipped with solenoid spark advance for starting check to make sure it is operating. To check disconnect leak to solenoid at bullet connector and energize solenoid momentarily with a jumper. The engine will speed up approximately 50 RPM and timing advance 7 1/2 deg if solenoid is operating.

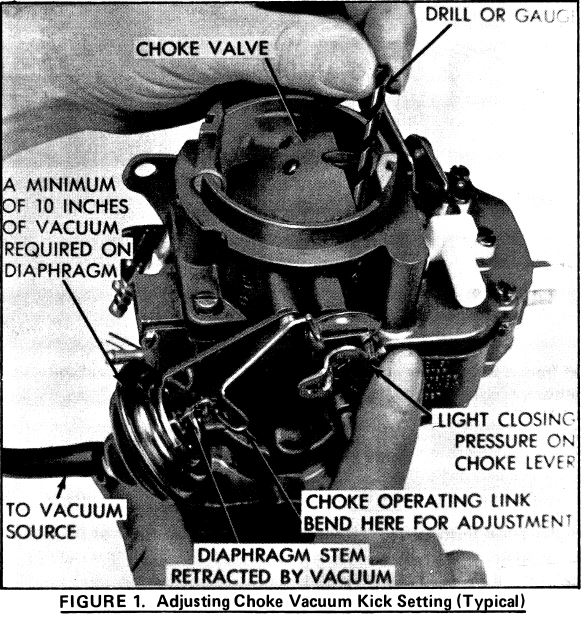

The carburetor choke vacuum kick locates the choke blade in the best position for good engine operation during warm up. If die out occurs during warm up check the vacuum kick adjustment. The following picture and description illustrates and describes a typical procedure.

Connect and auxiliary vacuum source to diaphragm.

While applying light closing pressure on choke lever check blade opening with a drill or gauge as specified. Refer to shop manual for specific carburetor involved.

Note: A tolerance of +- .015″ on 6 cyl engines and +- .10 on v-8’s is allowed on vacuum kick and cam index settings to permit adjustments for best engine operation.

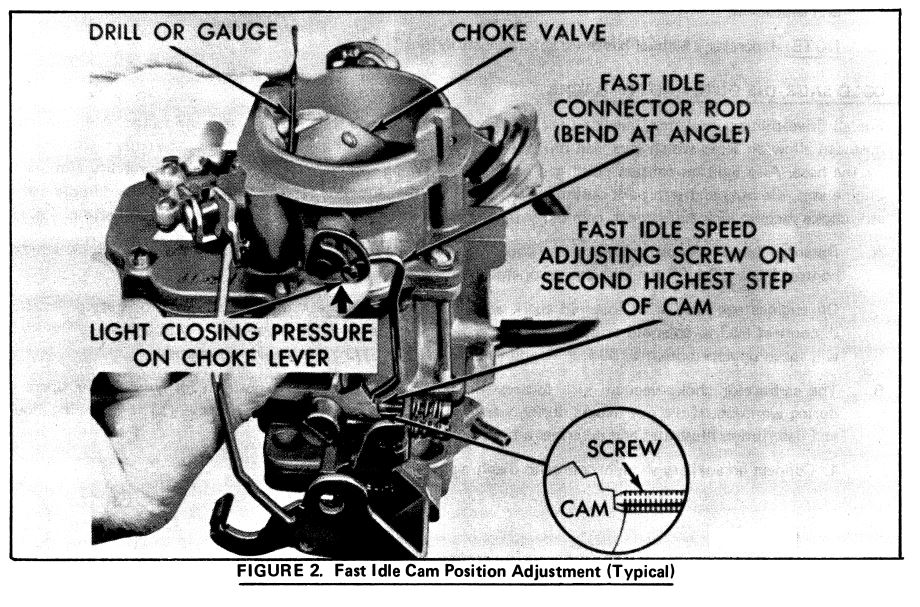

Fast idle cam index position is also important for proper engine speed during engine warm-up. The following figure 2 illustrates a typical procedure. With engine warm adjust fast idle speed on second highest step on cam.

Engine idle speed and idle mixture should be adjusted to specification according to the emission control label on car.

Warmed Up Low Speed Sags, Surges, Stumbles & Hesitation

Most of the above drivability complaints can be corrected by adjusting the basic ignition timing to specification, making certain vacuum advance is early enough, acceleration pump output is adequate and carburetor float setting is correct, and heat control valve is operating.

Basic ignition timing should be set to specification found on the emission control information label. It should be adjusted at specified RPM and with the vacuum hose to the distributor disconnected.

After setting initial timing, place carburetor throttle on step 2 of the fast idle cam. Check timing position, then reconnect distributor vacuum hose and note timing increase. If no increase in timing is noted, open throttle further until approximately 2500 RPM If no advance is noted check for vacuum at carburetor. If vacuum exists at fast idle, vacuum advance unit is defective.

NOTE: On all engines equipped with NOx control disconnect vacuum solenoid valve electrical leak before checking and reconnect afterwards.

If an exhaust analyzer is not available use the alternate procedure covered in the emission control label for the mixture adjustment. This will also assure correct throttle blade position.

The carburetor accelerating pump output can be check as follows:

- Remove the air cleaner.

- With the engine turned off open throttle fully. A strong full stream of fuel should discharge from the accelerating pump discharge nozzles.

- If the discharge is intermittent and inadequate check the pump plunger leather for a collapsed condition. Flare, if necessary. If the carburetor has a pump plunger with rubber cup check the sealing edge of the cup for cuts, etc.

- The fuel level in the carburetor is also important. Adjust, using the fuel level or float level specification. A tolerance of +_ .030 on the float height and +-.015 on the wet level is allowed to provide best engine operation.

- Check the exhaust manifold heat control valve for proper operation. The valve should remain closed during engine idle when cold or warm and crack open during acceleration.

- If slight surge at light load low speed operation persists check idle tubes for restriction. Care must be exercised in checking as enlargement can affect fuel economy and emissions.

Warmed Up High Speed Stumbles & Surge

If the above driveability condition exists in a vehicle the ignition timing should be checked and adjusted to specification and the vacuum advance checked for proper function.

In addition, carburetor high speed air bleeds and internal bowl vent should be checked to be sure they are open and not restricted, and carburetor float level set to specification.

If high speed persists the carburetor main jets and step up wires (if equipped), should be checked to assure that they are as specified for that particular carburetor.

Diminishing Well Bleeds

Some solid fuel models use diminishing well bleeds. This bleed is subjected to venturi pressure changes that follow engine load conditions. They serve as self adjusting air bleeds and at or near wide open throttle, could deliver fuel. The two center holes are the pump discharge windows and also the air bleed to prevent pump pull over.

Engine Idles Rough

Smooths out when adding a bit of gas to the carburetor throat. Ideas are not in any order.

- Weak fuel pump pressure. Test with a fuel pump tester. Check your manual for the exact measurement but should be around 4.5 lbs.

- Dirty fuel filter. Change the fuel filter every 6 months.

- Look for kinked or damaged fuel line that might be restricting fuel.

- Do you smell varnish? This happens when the engine has been sitting for months. Gas turns and varnishes the inside of the carburetor plugging the small passages. When cleaning you need to blow air through each passage while looking to make sure the air comes out the other end of the passage. Keep in mind that when this happens the gas tank and fuel lines will need to be removed and cleaned, otherwise you will have the same problem over and over.

- Float level is off keeping the gas level too low.

Doesn’t Start Well Under a Cold Start

- To start press the gas pedal down once. This does 2 things. Adds an extra squirt of gas from the accelerator pump the cold engine needs to get started. The 2nd thing is pressing the gas pedal allows the fast idle cam to move to the high position against the idle screw. This allows the RPM to move up to 1800 or so RPM. Check that these 2 things are happening.

- Test the thermostat. Is it closed when the engine is cold. Remember that the gas pedal has to be pressed a bit to allow the fast idle and choke to close.

- Once warmed up the thermostat should be open.

- Check the choke adjustments – it could be the choke is choking off the engine.