One of the butterflies is open about 1/8″ with the carburetor dis assembled.

1st check to make sure the fast idle linkage isn’t holding the valves open. Probably not since only one butterfly is open. Both valves should be closed. Someone has installed it improperly. When removing valves they should be marked so that they get put back the same way. When replacing them hold them tight against the wall while tightening the screw. When done you should see very little daylight around the valve.

If the secondary throttle plate is staying open, then check the primary shaft dog and spring.

What goes under the power piston.

A spring is inserted in the power piston hole, then the piston.

Fuel is puffing out nozzles on primary circuit at idle on primary carb of a dual carb set carbs were just rebuilt what is the cause.

I have taken this carb a part and rechecked floats adjustments and blown out passages with compressed air thank you

Make sure there is a check needle below the main discharge. Test the needle by holding it down gently with a brass drift punch. Put some fluid in the accelerator pump well and press down on the pump. You should feel some pressure and fluid should not be bypassing the check needle. If it is, tap gently with a hammer and the same brass drift punch to seat it, or replace the check weight.

Each float on the float assembly should be at the same height and centered so that they don’t rub the side of the float bowl. Test the floats in hot water and if you get any bubbles then they are leaking.

Test the fuel pump to be sure it isn’t putting out too much pressure. You will need to check your motors manual for the spec, but around 4 or 5 should be plenty. New fuel pumps are especially suspect.

Gas is coming out of the vent

You are flooding (getting too much gas in the float bowl), caused by these types of problems.

Float adjusted wrong – check float level.

Float leaking – heat up some water and immerse the float. Any bubbles indicates a leak.

Make sure the 2 floats are the same height. Also make sure one isn’t rubbing on the side. They need to be centered in the bowl.

Fuel could be leaking around the needle & seat. Did the old gasket get removed? Look for breaks in the new gasket, or cracks around the threaded area.

The needle could have been damaged while adjusting the floats. Any pressure put on the needle will damage it. Examine the viton tip for any marks.

Fuel pump pressure could be too high. Check your auto manual for the spec, but somewhere around 4-5 lbs would be good.

Be sure the power piston is not frozen in one position. It needs to go up and down easily.

Is there a spring under the power piston?

Are the venturi cluster gaskets sitting flat and not curled over? They sometimes need trimming.

When I slow down to an idle, my engine runs rough.

Two ports act as calibrated air bleeds. One is in the secondary venturi and the other just above the throttle plate. Be sure these ports are clear.

Percolation

When the engine gets hot and then is shut off, gas can sometimes overheat and then boil. This is percolation.

The high speed air bleed and the secondary bleed tube also acts as an anti-percolator. Make sure these are clear if you have percolation problems.

Also check for overheating of the engine, fuel lines too close to the manifold, or too much heat in the engine department.

Try other brands of gas.

Squirters are not working.

They work fine when I push hard down on the piston. Piston force is too much for linkage.

There may be a blockage in the accelerator pump circuit which would also make it hard to pump.

What is the carburetor number so we can make sure you have the correct pump?

Polish the pump well with crocus cloth. Ethanol gas does not have much if any lubrication. Run a blunt object around the inside of the leather cup to make sure any coating is broken. Some have a coating to give it a better shelf life.

Add a couple drops of oil to the leather. Is there a pointed check weight in the main discharge hole.

Dies when choke opens

- Engine won’t idle, or dies after the choke is opened, or runs better when choke closed

- Curb idle speed is set too low.

- Gasket between bowl and base is installed backwards (easy to do).

- Vacuum leak downstream of carb.

- Secondary’s are somehow stuck open (which amounts to a vacuum leak).

- Not enough fuel in the float bowl

- Sticky float valve

- Low fuel pump pressure – always check you motors manual for the correct pressure. Probably around 4- 4.5lbs

- Clogged idle tube, or passages in the idle circuit.

Slight stumble off idle.

The off idle problem may be a restriction in the idle circuit. When accelerating, the throttle valve starts to open and uncovers the discharge port. This gets you from idle to where the accelerator circuit takes over. These are small passages and get plugged with carbon. Look at the discharge port where the idle mixture is inside the bore. Just above that will be another hole, or perhaps a slot, can’t remember which. See the illustration below, but follow the passages including the idle air bleeds to make sure they are open.

I purchased from you a rebuild kit for Carter WCFB 4 barrel carb on my 1955 Chev. Fuel pump working as it should (pulsates and sprays gas each time cam lobe activates it). Though fuel float bowl full, can’t get gas into the accelerator pump chamber of the carb. Can fill the accelerator chamber with a syringe (through top open passages of forward barrels where choke butterfly is) and the jets will spray gas into forward chambers (and will idle and accelerate for about 15 seconds)but when that gas is depleted, the spraying stops. I have repeated multiple times with same results. Can you help me out? One caveat…it’s my “impression” that the float bowl is full because when I disconnect the fuel supply line from fuel pump (to card), it has pressure on the line. In my repeated attempts to get the accelerator valve to pump, the car has run for several minutes combined…plenty of time to get the float bowl full. Could the float bowl actually be the problem? Ideas??

A fuel pump cannot be tested by unhooking the line and seeing if gas comes out. The correct way is to use a fuel pump pressure gauge. It needs about 4 lbs of pressure.

As for the pump not squirting.

I suspect the pump well isn’t filling up. Take the top off and put the pump in the well all the way to the bottom. With mineral spirits in the float bowl, Raise the pump. The well should fill with fluid. If not, then find the check ball and make sure it is loose. On the WCFB the check ball is usually at the bottom of the pump well. There should be a retainer keeping the check ball in place. Make sure the ball rattles. If not then clean it and try again.

If the fuel bowl is not filling up enough to fill the pump well, then look at a sticking float needle. Float drop not set, or fuel pump pressure too low.

Engine Stalls on Left Turns

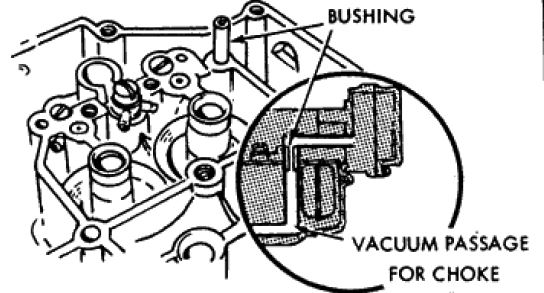

A bushing (sorry don’t have size) can be permanently installed in the choke vacuum passage in main body casting provides a more positive seal at this point, and prevents fuel from leaking into this passage on left turns and stalling the engine because of too rich a mixture. Make sure the air horn contacts the inner wall of the bowl. This can be done by looking at the impression on bowl cover gasket. Correct by removing any burrs or nicks. Recheck float adjustments.

Bowl Cover Screws

Different lengths

All late model WCFB carburetors have three different length bowl cover screws. Each size must be used in its own location.

1955 Chevy – Loading on Warm Up

Reset choke housing to 2 points lean.

1955 Chevy – Hard starting after flooding

Check throttle linkage to make sure that primary throttle valves come to full wide open position. Recheck unloader settings with carburetor on the engine.

1955 Chevy – Air Cleaner Installation

Make sure the air cleaner gasket does not block the bowl vents. Check to see that slots in air cleaner gasket line up with vent tubes and do not rotate gasket during installation of air cleaner.

1955-56 Desoto – Engine Stalling

Readjust idle to 500 RPM and fast idle to 1200 RPM On 1955 models set choke two points lean. On 1956 models one point rich. Readjust dashpot plunger to move 1/16 inch on closing of throttle valves. Make sure manifold heat control valve is free.

1957 Desoto Adventurer – Loose Throttle Lever Rear Carburetor

This is caused by side strain on throttle lever due to misalignment and maladjustment of the carburetor interconnection rod. To correct, remove carburetor and tighten throttle lever by either peening end of shaft over, or soldering end of shaft to throttle lever. Reinstall carburetor, align and readjust inter connecting rod to manufacturer’s specifications.

1957 Hudson, Nash, Ramber – Rough Idle

With engine running, check for an air leak at front left corner of carburetor between throttle body and bowl by squirting carb cleaner at this point. If a loss of rpm is noted, or if the engine dies, and air leak exists. To correct, remove carburetor and turn it upside down. Place the choke housing toward the left and remove upper right main body to throttle body screw. Coat threads of screw with sealing compound and install it.

1956 Plymouth, Powerflite Transmission – Dashpot

The dashpot has been eliminated.

1955 Pontiac – Loading or Carburetor Flooding

Test fuel pump for excessive pressure.

1956 Pontiac – Hard Starting, Partially Warm Engine

Change the choke setting to index. If hard starting still exists change the choke setting to one point lean.