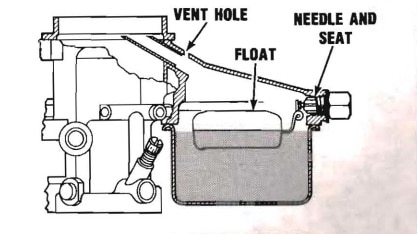

The float assembly in the RBS is compact for extreme rigidity assuring little or no change in float setting due to vibration or heat. The cellular nitrophyl float is impervious to denting under normal handling and is not susceptible to punctures, assuring a constant buoyance factor. Nitrophyl floats will, however, absorb fuel over time and should be replaced during a rebuild.

The bowl is vented to the inside of the air horn through a single pressed-in tube located in the main casting. Some models include an additional small outside vent hole located in the bowl cover. These balanced or semi-balanced vents automatically compensate for increased air cleaner restrictions which might reduce fuel economy. An additional outside vent is provided for the fuel bowl (at upper end of plunger shaft) during idle and engine off mode.

A vapor vent hole, drilled into the bore of the carburetor above the throttle valve aids in faster hot engine restarts. It prevents the accumulation of fuel vapors in the bore of the carburetor by allowing them to escape to the atmosphere.

Some later models use a mechanically operated bowl vent valve located internally in the main casting above the fuel bowl. At curb idle, the pump linkage opens the valve to allow fuel vapor to exit to the vehicle’s vapor storage system.