Importance of fuel pressure in traditional EFI and modern DI systems

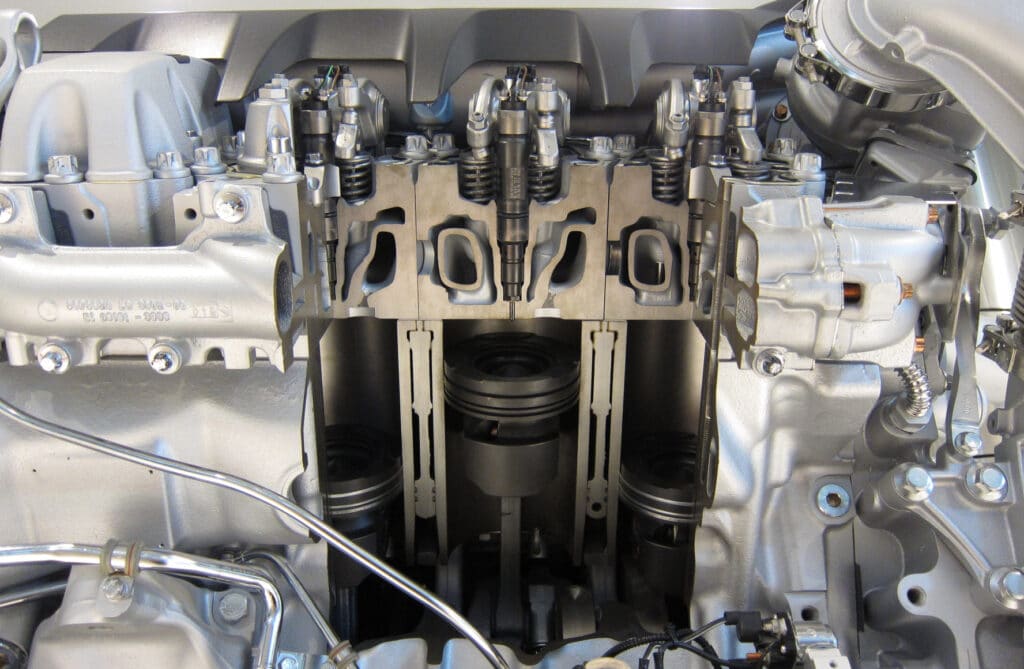

Fuel pressure has always been a key aspect of the fuel delivery system. However, newer vehicles using direct injection (DI) systems, also known as gasoline direct injection (GDI) systems, have raised the importance of proper fuel pressure to a new level.

In this video, we are going to explore how fuel pressure affects vehicle performance and fuel economy, both for traditional port injection and most recent DI systems.

How fuel pressure is controlled

Let’s start by taking a quick look at the factors that determine how much fuel pressure reaches the injectors at any given time.

- Fuel pump capacity. As you might expect, the fuel pump is the main factor that determines the amount of fuel that reaches the combustion chamber. The reason is very simple if the fuel pump fails no fuel arrives at injectors, thus all other factors became irrelevant. Moreover, beyond “having pressure” the system needs the “appropriate pressure” to perform as intended. In that sense, the capacity of the fuel pump must be adequate to satisfy the demand of the engine.

- Electronically-controlled Pulse Width Modulation (PWM). There was a time when fuel pumps supplied a constant flow of fuel at a given pressure. No more. For years electric pumps have been directly controlled by the vehicle’s computer which “modulate” the flow of fuel to the engine. Thanks to this modulation, the computer can increase or decrease the amount of fuel delivered by changing the fuel pump rotation speed as needed.

- Fuel pressure regulator. Since electronic fuel injection systems became popular in the 1980s, there have always been mechanisms that regulate fuel pressure. In traditional MPI (Multi-Port Injection) systems this regulation is done either by a fuel regulator controlled by the engine vacuum, or a mechanically calibrated regulator located in the fuel filter or the fuel pump module. In modern DI systems, this function is accomplished by fuel pressure sensors that allow the computer to adjust the fuel pump speed when necessary.

The recommendation that we give you at Mike’s Carburetor Parts is that when replacing a fuel pump, always check that it is 100% compatible with your vehicle. Contrary to what many people think, a larger capacity pump is not always a good idea. Remember, any change to the electric fuel pump will require modifying the rest of the fuel system, as well as making the necessary adjustments to the engine (calibrating high-pressure fuel pump on DI systems) and recalibrating the on-board computer.

Factors that affect fuel pressure

Checking fuel pressure is always a good idea. To achieve this you will need a pressure gauge or an automotive scanner depending on the year and model of your car. Below we list the main factors that could explain low fuel pressure.

- Faulty fuel pump. As explained earlier, the fuel pump plays a crucial role in the fuel delivery system. A bad or even a faulty fuel pump could significantly affect fuel injection systems. In conventional MPI systems, a 10% drop in fuel pressure will start to cause engine problems, while a 15% -25% drop can even cause the engine to stall. In most modern systems with direct fuel injection, the situation is even more critical. A drop of just 2% is already enough for the engine not to operate properly.

- Dirty fuel injectors. Many people underestimate the importance of keeping fuel injectors free of carbon deposits, dirt, and other harmful agents. Here at Mike’s Carburetor Parts, we see it daily. When the injectors become clogged, both fuel flow and spray are affected. That directly affects the fuel pressure required for the vehicle to function properly. The need for higher pressure to compensate for this situation decreases both the life of the fuel pump and the injectors. That is why we recommend preventive maintenance of the injectors, either by using an ultrasonic cleaner or fuel injector cleaners.

- Clogged fuel delivery system. Fuel injectors aren’t the only ones that can get clogged. The in-line fuel filter, the fuel pump pre-filter, and even the fuel line itself if it gets damaged can hinder the free flow of fuel to the injectors. This type of situation lowers the effective fuel pressure which in turn impacts the entire system.

Without a doubt, timely maintenance is crucial to prevent fuel supply problems. At Mikes’s Carburetor Parts we can help you with the most advanced ultrasonic injector cleaning system on the market, as well as replacement injectors fully compatible with your vehicle.

Symptoms of low fuel pressure

Symptoms of a bad fuel pump, clogged injectors, or problems with the fuel lines and filters can vary slightly depending on whether your vehicle uses an MPI or GDI system. Here is a list of the most common symptoms of inappropriate fuel pressure.

Poor fuel economy. Without adequate pressure to achieve an optimal air/fuel mixture, combustion efficiency will drop and therefore fuel consumption will increase significantly.

Noticeable decrease in engine power. Another direct consequence of improper fuel pressure will be a noticeable drop in engine performance. This decrease in power will be more noticeable when accelerating, especially uphill or under load.

Engine stall under heavy load. Even if the pressure drop is not too great, the engine can stall if you put a lot of load on it. This type of situation is more common in four-cylinder engines as they are more prone to working at the limit when subjected to high loads.

The vehicle may not start. If the mixture is lean enough, a situation may arise where the engine fails to start. This situation is more common when the engine is cold since it requires a greater amount of fuel than when it is hot.

Engine knocking. As the air/fuel mixture becomes leaner, the temperature of the combustion chamber increases. This increase in temperature favors engine knocking, which is a situation that must be addressed in time to avoid serious damage to the pistons.

Engine misfires. Similar to engine knocking, when combustion efficiency is altered, it is very common for spontaneous misfires to occur in different cylinders. The frequency and intensity of these misfires will be determined by the fuel pressure, the lower the pressure, the greater the failure.

Backfires in the exhaust when accelerating. Another symptom that can be seen when the mix is too lean is backfiring. When there are little fuel and a lot of air in the combustion chamber, the spark plug often fails to ignite the entire mixture. The part of the air/fuel mixture that does not burn in the chamber comes out along with the exhaust gases and can spontaneously ignite at any point causing the explosion.