The amount of fuel supplied to an engine is controlled by the size of the power jet, the position of the power adjusting needle, and the difference in air pressure between the fuel bowl chamber and the venturi. However, in many engines the mixture must be leaned out additionally during part throttle operation to obtain maximum economy. To provide this leaner mixture Marvel-Schebler Tractor and Industrial Carburetors make use of the “Back Suction Economizer System. With this method of metering fuel, the air pressure in the fuel bowl chamber is regulated and controlled according to load conditions by a combination of bowl vent and economizer passages communicating with the throttle bore of the carburetor. Through regulations of the air pressure in the fuel bowl chamber the fuel flow through the carburetor can be controlled to provide the proper mixture proportions for the engine.

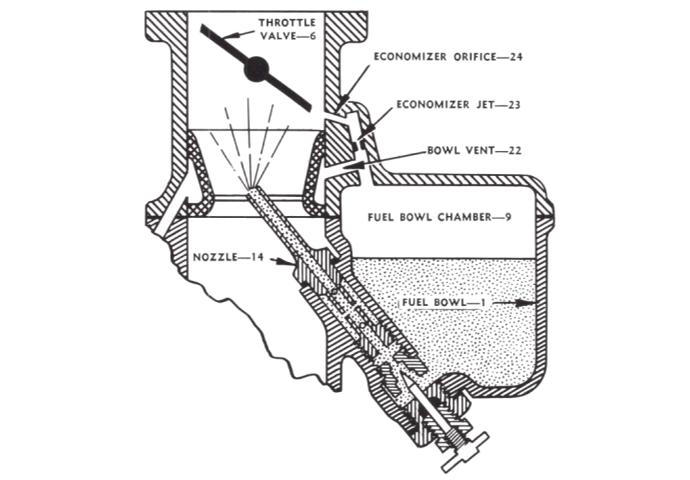

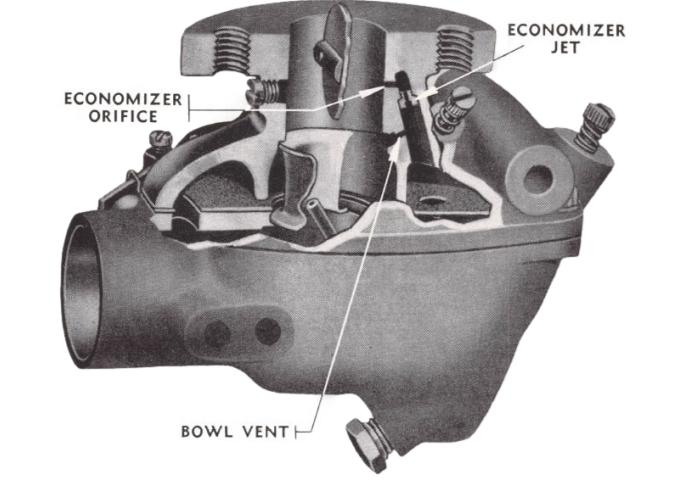

All the air that enters the fuel bowl chamber (9) must first pass through the air cleaner and the bowl vent (22). The size of the bowl vent (22) controls or limits the amount of air that can enter the fuel bowl chamber (9). The amount of air that is drawn out of the fuel bowl chamber (9) is controlled by the size of the economizer jet (23), the economizer orifice (24) and the position of the throttle valve ( 6) as its position determines the manifold vacuum or suction on the economizer orifice (24). As the throttle valve (6) is opened from the fast idle position the economizer orifice (24) is gradually exposed to manifold suction, and air flows from the fuel bowl chamber (9), through the economizer jet (23) and out the economizer orifice (24). This air must be replaced by air entering through the bowl vent (22) but as the size of the bowl vent

(22) restricts the amount of air that can enter, the resultant pressure in the fuel bowl chamber (9) will be lowered, reducing the difference in air pressure between the nozzle (14) and the fuel bowl chamber (9). The flow of fuel will therefore be retarded so that the exact economy mixture ratio will be delivered to the engine at this particular throttle opening. Opening the throttle valve ( 6) further exposes the entire economizer orifice (24) to manifold suction, resulting in additional air being removed from the fuel bowl chamber (9), again leaning out the mixture ratio to the correct proportions for this new throttle position. After the economizer orifice (24) is fully exposed to manifold suction the amount of air that is drawn out of the fuel bowl chamber (9) is controlled by the manifold vacuum or suction at any given throttle valve ( 6) position and as this suction decreases as the throttle approaches wide open position, less air is drawn out of the fuel bowl chamber and additional fuel flows to the engine to provide the extra richness required for operation at heavy loads where maximum horsepower is necessary.

The “‘Back Suction Economizer System” assures the proper metering of fuel to the engine throughout the service life of the carburetor as there are no moving parts to wear out or adjustments to get out of order. It is essential, however, that the system remain free of dirt and foreign matter because any foreign substance in the system will restrict the flow of air thereby creating improper pressures in the fuel bowl chamber and resulting improper fuel delivery to the engine.