The adjustments shown here are meant to be a guide, actual specifications are included in our carburetor rebuild manual. We offer these manuals for purchase on our website, they are provided free to our customers that purchase rebuild kits.

Gauges and special tools are no longer available for carburetors. Anywhere that the instructions reference a ‘gauge’ we now use measurements.

Float Level Adjustment

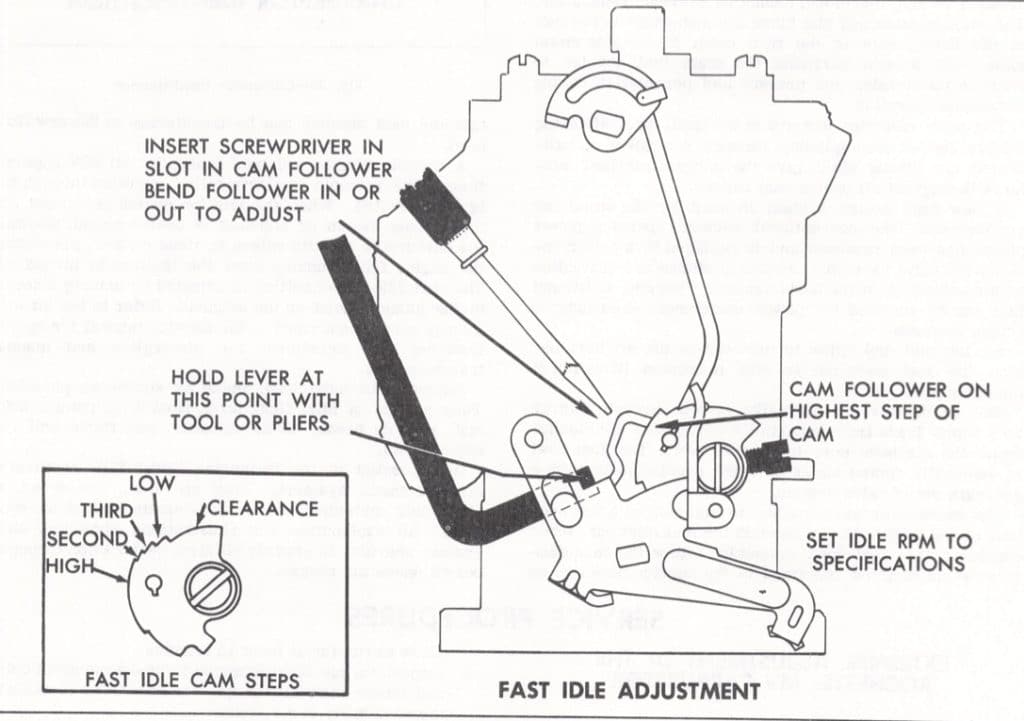

Fast Idle Adjustment

The fast idle adjustment must be set with electrical lead to the transmission controlled spark solenoid disconnected and transmission in neutral.

- Make slow idle speed and mixture adjustments with engine at normal temperature and transmission in drive.

- Place fast idle cam so that cam follower tang is on the highest step of the fast idle cam.

- Fast idle speed should be be as specified. If not, insert a screw driver in slot on cam follower tang and bend tang as required to obtain specified speed.

- Connect electrical lead to TCS solenoid.

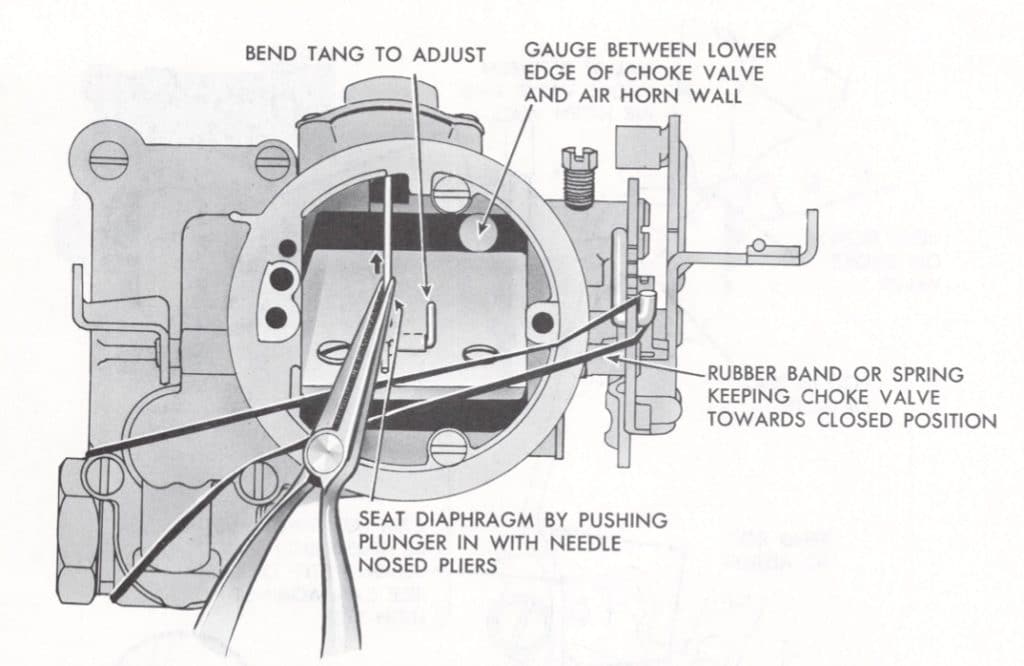

Vacuum Break Adjustment

- Remove air cleaner assembly from vehicle

- Rotate choke valve to close position

- Hold choke valve close with rubber band attached between the choke shaft lever and stationary part of carburetor as shown in right hand image

- Grasp vacuum break plunger rod with needle-nosed pliers and push straight inward until diaphragm seats

- With specified gauge, measure celarance between lower edge of choke valve (center of valve) and inside air horn wall

- Bend the tang on the end of vacuum break lever at point shown to adjust.

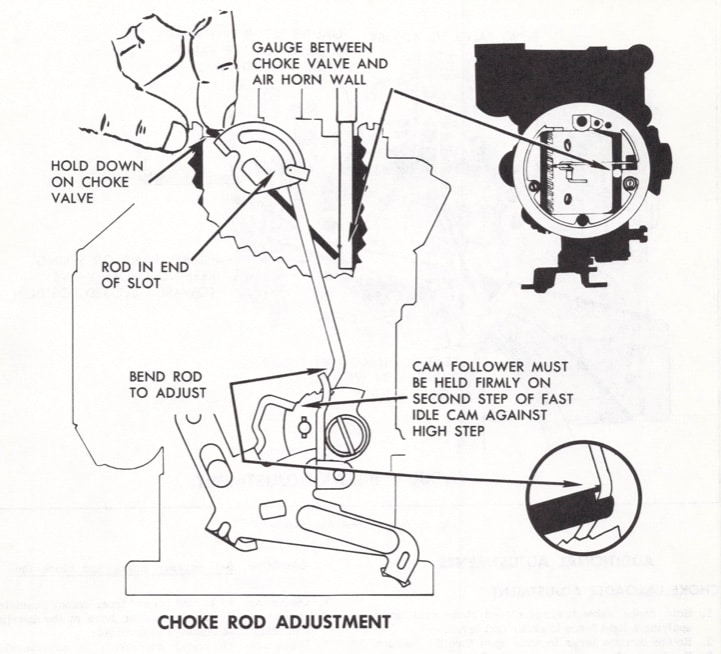

Choke Rod Adjustments

- First set fast idle adjustment

- Place fast idle cam follower on second highest step of fast idle cam and hold firmly against rise to high step

- Rotate choke valve towards direction of closed choke by applying force tot he choke coil lever

- Bend the choke rod at point shown to give specified opening between the lower edge of choke valve (at center of valve) and air horn wall.

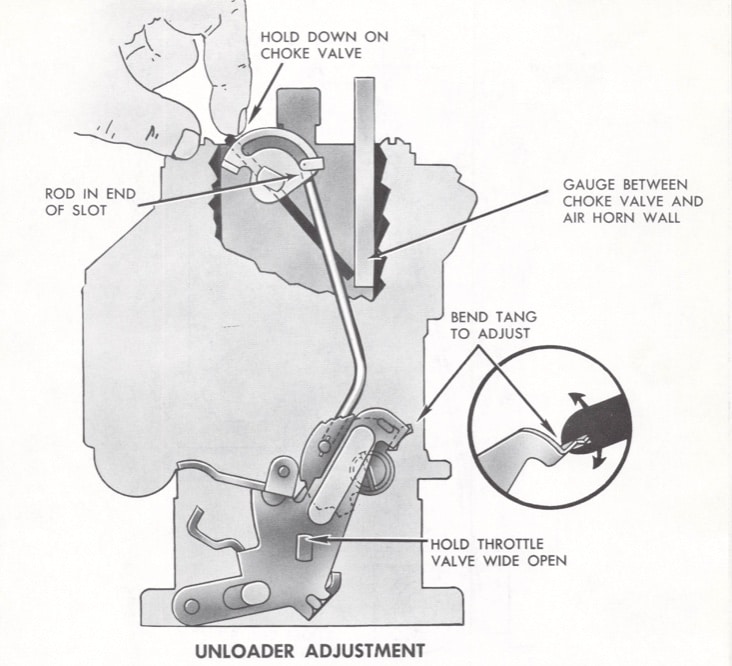

Choke Unloader Adjustment

- Hold choke valve towards closed choke position by apply a light force to choke coil lever

- Rotate throttle lever to wide open throttle position.

- Bend unloader tang on throttle lever to obtain the specified dimension between the lower edge of choke valve and air horn wall

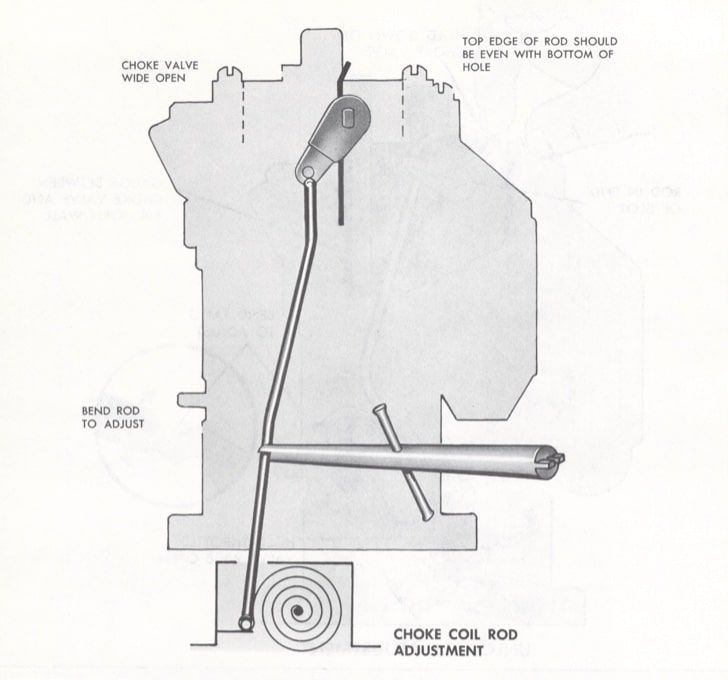

Choke Coil Rod Adjustment

- Hold choke valve complete open

- With the thermostatic coil rod disconnected from the upper lever, push downward on rod to end of travel

- With the rod in the fully downward position, the top of rod should be even with the bottom of hole in lever as shown in the image above

Idle Mixture Adjustment

- Warm your engine up to operating temperature.

- Set the curb idle to specification. Check your motors manual. Probably around 600 RPM.

- Turn the idle mixture screw out 1/2 turn in case it is already turned in (clockwise) too much.

- Turn the idle mixture screw clockwise 1/4 turn and let the engine catch up to the adjustment.

- Once the RPM starts to drop, turn the screw back out (counter clockwise) 1/4 turn.

If the idle mixture screw doesn’t make any RPM difference then you have either a vacuum leak, or a problem in the carburetor.

You can also connect a vacuum tester to the intake manifold and adjust the idle mixture screw to get the best and smoothest vacuum at idle.

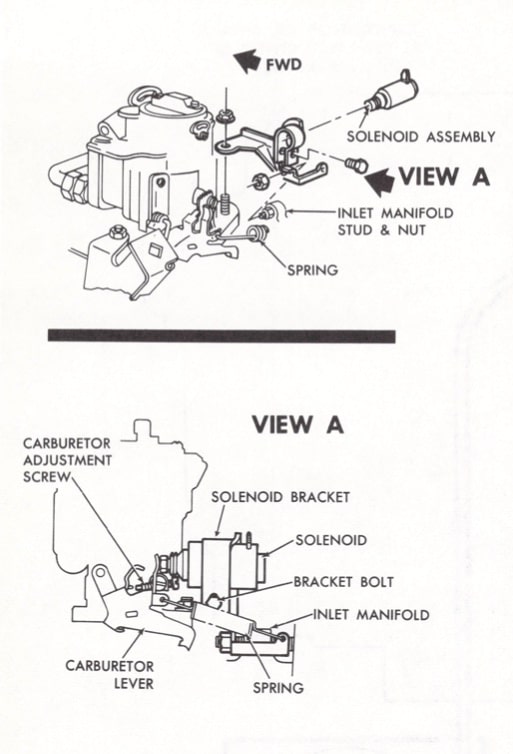

Anti-Dieseling Solenoid Adjustment

With engine at normal operating temperature, air cleaner on, choke open, and air conditioning on if so equipped.

- Disconnect fuel tank hose from vapor canister

- Disconnect distributor vacuum hose at the distributor. Plug hose leading to carburetor

- Disconnect electrical connection at anti-dieseling solenoid

- Set dwell and timing at specified RPM

- Adjust carburetor speed screw to specified RPM

- Reconnect electrical connection at anti-dieseling solenoid. Open throttle momentarily and adjust solenoid screw to specifed RPM

- Reconnect distributor hose and fuel vapor hose at canister