Adjusting the Idle Mixture

Your engine should be at operating temperature. Adjust the idle to manufactures specifications for your particular vehicle. Be sure your choke valve is all the way open and the fast idle cam is at the lowest spot. On the Monojets that use the electronic solenoid, disconnect the solenoid, then adjust the idle using the solenoid.Turn the idle mixture screw out about 1/2 turn, then start turning it in 1/4 turn at a time, wait a second so the engine can catch up. Do this until the engine rpm starts to drop. Turn the screw back out (counter clockwise) 1/4 of a turn. Another way to adjust the idle mixture is to attach a vacuum gauge to the intake manifold, using one of the vacuum ports (use one off of the carburetor throttle body). Same idea here. Turn the idle mixture screw in until the vacuum starts to drop, then turn it back out to get the best steady vacuum reading. If the rpm doesn’t change then you have a problem. The carburetor is either dirty and needs cleaning, or you might have a vacuum leak. Most likely it is dirty assuming it wasn’t recently cleaned.

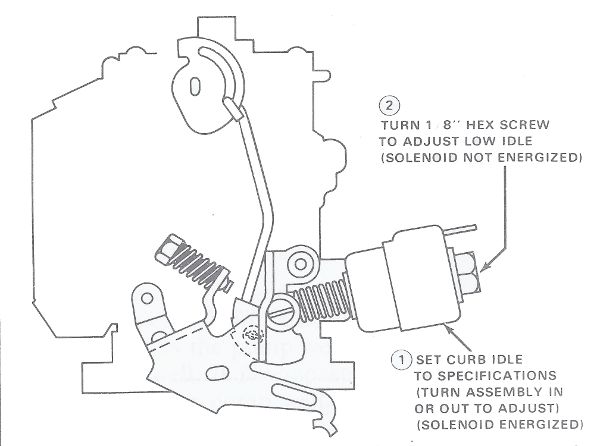

This illustration shows the idle stop solenoid on a carburetor that also has a C.E.C (Combination Emmision Control) valve. You may not have this on your carburetor. While the idle stop solenoid would be nice to have, they are not available these days. Most rebuilders will replace this with a bolt and the bolt is used to adjust the idle.