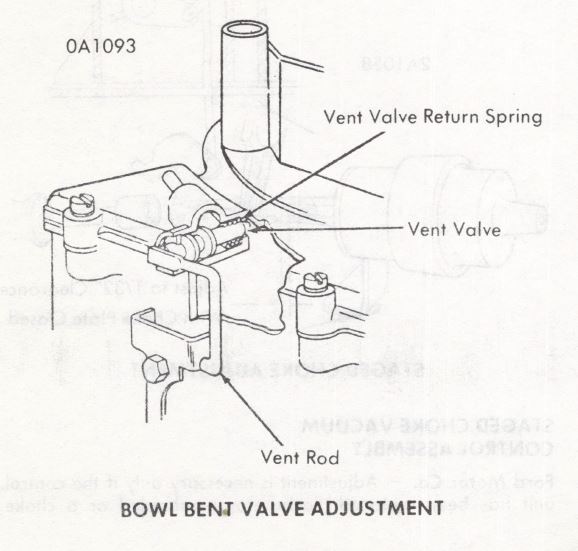

Fuel Bowl Vent Valve

The fuel bowl is vented through an external vent connected by a hose to fuel evaporation carbon canister.

Fully depress vent valve into valve bore. Measure clearance between flat portion on vent rod and fully seated valve.

If adjustment is required, bend vent rod at point where it contacts accelerator pump lever.

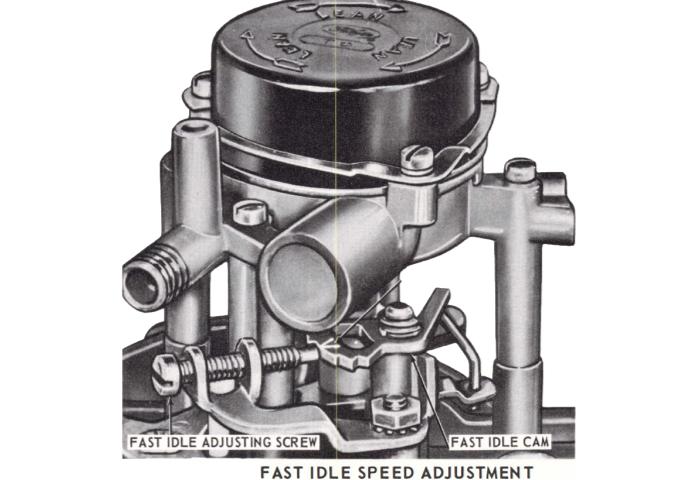

Fast Idle Adjustment

The fast idle adjusting screw contacts one edge of the fast idle cam. The cam permits a faster engine idle speed for smoother running when the engine is cold, during choke operation. As the choke plate is moved through its range of travel from closed to open, the fast idle cam pick-up lever rotates the fast idle cam. Each position on the fast idle cam permits a slower idle rpm as engine temperature rises and choking action is reduced.

Make sure the curb idle speed and mixture settings are adjusted before attempting to set the fast idle.

The following adjusting procedure is suggested:

- With the engine at normal operating temperature, air cleaner removed and tachometer attached, manually rotate the fast idle cam until the fast idle adjusting screw rests on the second (kickdown) step of the fast idle cam.

- Turn the fast idle adjusting screw inward or outward, as required to obtain the specified fast idle rpm.

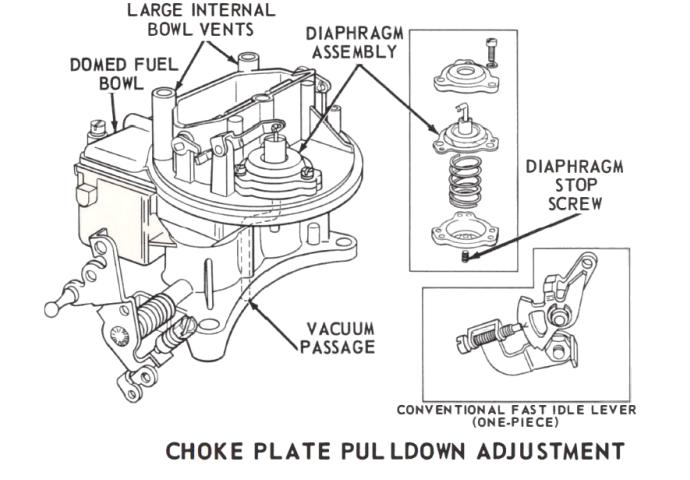

Choke Plate Pulldown Adjustment

The vacuum-operated choke modulator is used in place of the vacuum piston. It tailors initial choke opening after engine start, to the existing temperature requirement.

The following adjusting procedure is suggested:

- With engine at normal operating temperature, loosen thermostatic spring housing retainer screws and set the housing 90° in the rich direction.

- Disconnect and remove the choke heat tube from the choke housing.

- Turn the fast idle adjusting screw outward one full turn.

- Start engine and check for the specified clearance between the lower edge of the choke plate and the air horn wall.

- If the clearance is not within specifications, tum the diaphragm stop screw (located on the underside of the choke diaphragm housing):

• Clockwise to decrease clearance.

• Counterclockwise to increase clearance. - Connect choke heat tube.

- Set choke thermostatic spring housing to specification.

- Adjust fast idle speed to specification.