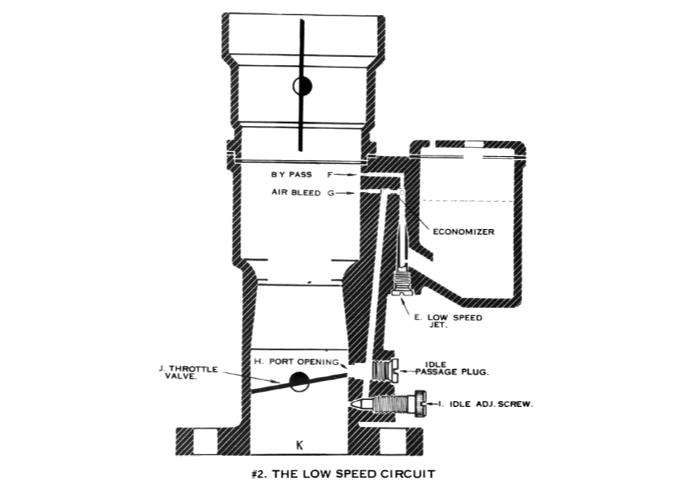

The Idle or Low Speed Circuit completely controls the supply of gasoline to the engine during idle and light-load speeds up to approximately 20 m.p.h. and it partially controls the supply for light-load speeds between 20 and 30 m.p.h.

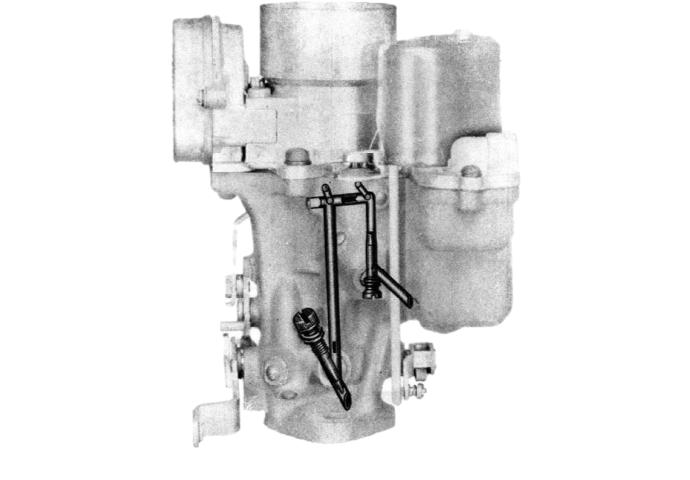

The idle or low speed circuit consists of the low speed jet (E), by-pass (F), economizer, air bleed (G), port opening (H), idle adjusting screw (I), throttle valve (J), throttle shaft, carburetor bore (K).

During idling and low speed operation of the engine, gasoline flows from the float bowl through the idle speed jet to the point where it is combined with a stream of air coming in through the by-pass (F). The combining of the stream of air with the stream of gasoline tends to atomize or break up the gasoline into a vapor.

This mixture of air and gasoline continues on through the economizer until it begins to pass the point where it is further combined with a stream of air coming in through the lower air bleed (G). This again, tends to break the gasoline particles into a finer vapor. The gasoline

and air mixture that flows downward in the passage from the lower air bleed (G) is still richer than an idle mixture needs to be, but when it mixes with the air which has come past the throttle valve, it forms a combustible mixture of the right proportions for idle speed. The idle port (H) is made in a variety of slotted shapes so that as the throttle valve is opened, it will not only allow more air to come in past it, but will also uncover more of the idle port, allowing a greater quantity of the gasoline and air mixture to enter the carburetor throat from the idle mixture passage.

The idle position of the throttle is such that at an idle speed of 6 m.p.h., it leaves enough of the slotted port as reserve to cover the range in speed between idle and the time when the high speed system begins to cut in. The idle adjusting screw (I) varies the quality of the idle mixture. All the gasoline flowing from the float bowl during the idle period and at no-load speeds up to 20 m.p.h., flows through the small metering hole in the low speed jet. This hole is held to a manufacturing tolerance of .00025 and is a very important factor in controlling the flow of gasoline into the engine during these speeds. It should never be cleaned out in any other way but by compressed air. as small wires and drills tend to increase the size of the hole, thereby changing the calibration of the carburetor. Naturally, it would take a very small particle of dirt to restrict the passage of gasoline through this hole and totally destroy the idle of the engine.

The-outside of the barrel of a new low speed jet is straight from the base to the tip; but, as it is installed in a carburetor, the tip of the barrel contacts· the tapered seat in the body of the carburetor between one and two complete turns of the jet before it is fully installed.

As the jet is screwed into place, a gasoline tight fit is made between the tip of the jet and the body of the carburetor by the rolling and tapering ‘3.ction of the tapered seat.