Mercarbs are used on later model marine applications and are often confused with the Rochester 2jet carburetor.

The Mercarb is easily identified by it’s single idle mixture screw, while Rochester carbs have two screws.

If you need help determining whether you have a 2jet or a Mercarb, watch our quick identification video.

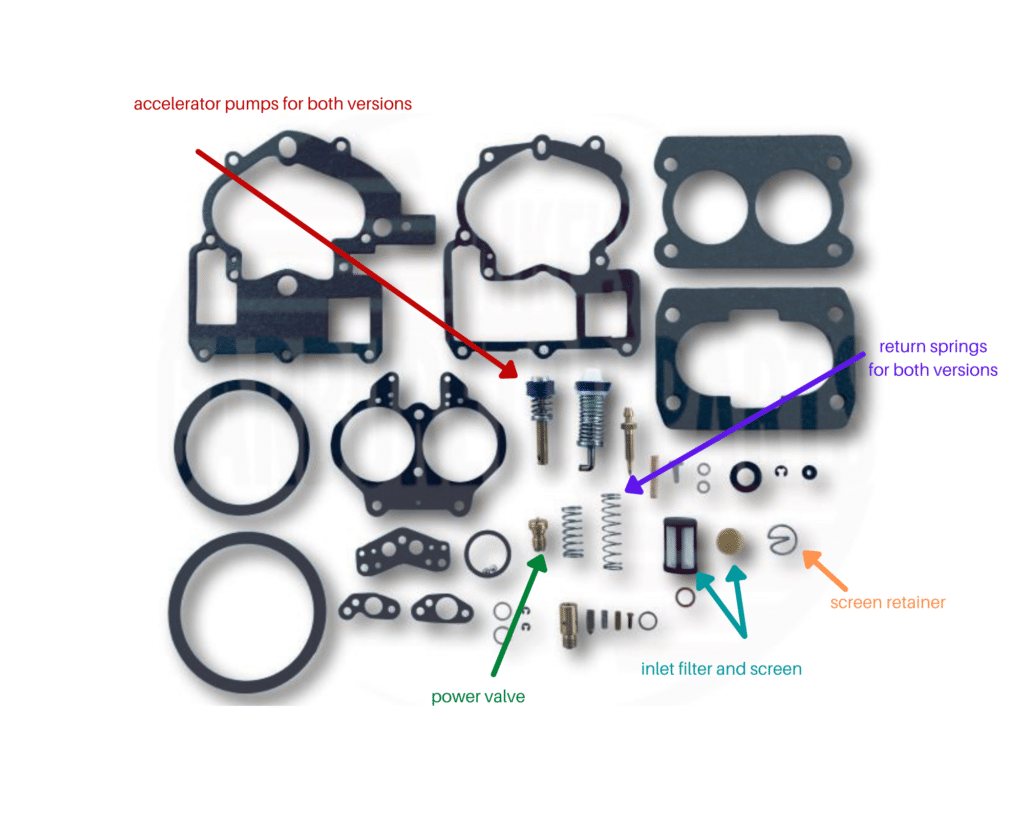

For this particular style of Mercarb, there were two basic versions.

To make it easier to purchase a rebuild kit, we’ve created a master kit that covers both versions. No need to remove your carb before having replacement parts in hand!

We also include parts not found in standard kits.

Individual component parts for the Mercarb are available on the website as well, see the full catalog here.