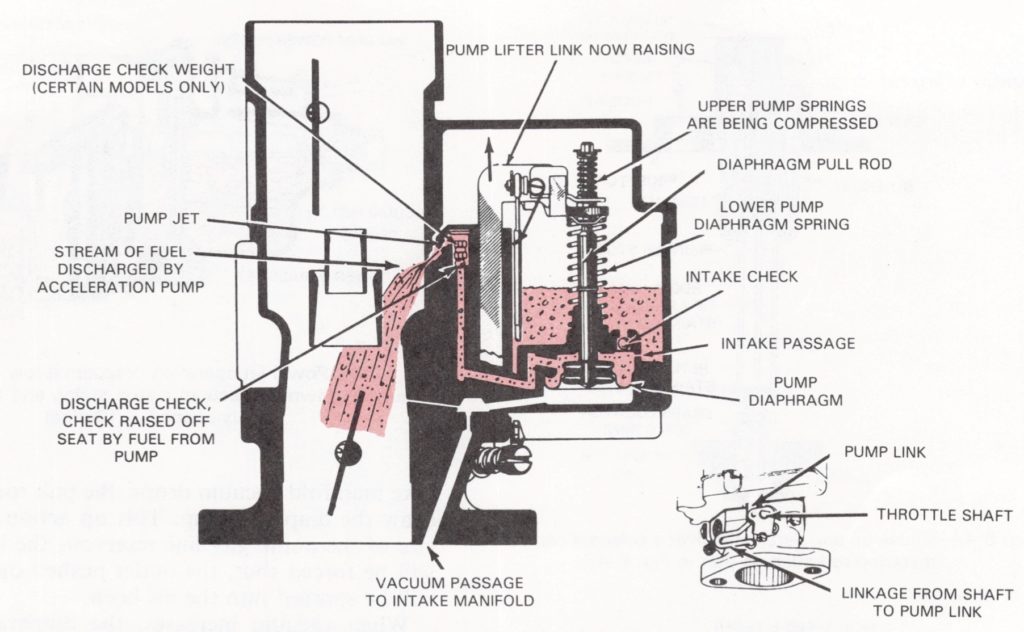

The below illustrates a Carter YF carburetor, other models will work in a similar way.

An accelerator pump using either a piston or a diaphragm is part of every carburetor. The image above shows a diaphragm type which is connected to a pull rod which, in turn, is fastened to a lifter link

A spring is placed on the pull rod, both below the link and above. The lower spring is the strongest and is designed to keep the diaphragm up against the pull of the vacuum chamber below the diaphragm. Normal vacuum, however, will overcome the spring tension and hold down the diaphragm.

As in the case of the metering rod, the moment intake vacuum drops, the pull rod spring will draw the diaphragm up. This up action reduces the size of the pump gasoline reservoir, the intake check will be forced shuft, the outlet pushed open and fuel will be sprayed into the air horn.

When vacuum increases the diaphragm will be drawn down. This shuts the discharge check and draws gasoline through the intake check, filling the pump reservoir.

The very same action takes place when the throttle valve is opened. This raises the pump link mechanically and forces the diaphragm up.

The pump can discharge fuel into the air horn either through the main fuel nozzle or through one or more special pump discharge jets. Some carburetors control the pump diaphragm or piston with linkage only, others use linkage and vacuum. The pump shown in the carburetor image above uses both.

In additiona to an intake check in the above carb, there is also a tiny intake passage. This passage will let a measured quantity of fuel return to the bowl during the pump stroke. Some carburetors do not use this system.

The springs on the pump rod are important. If the pump lifter link is suddenly raised by hitting the throttle hard, the springs prevent the pump from being smashed against the pump bore. Instead, the link raises and compresses the top spring. The tension of the spring will quickly and smoothly draw the diaphragm up. Instead of short fast burst of fuel, you get a smooth stream.

When the link is suddenly dropped by releasing the accelerator, the diaphragm will be squashed down, since the link will slide down the pull rod and the diaphragm will be pulled down by vacuum. The top spring acts as a bumber during this down movement.

The amount of fuel discharged by the accelerator pump depends on the size of the piston and the length of the piston stroke. In some carburetors a thermostatically controlled bypass permits part of the pump discharge to flow back into the bowl when engine temperatures are such that a full discharge is not needed.

Mechanically operated pump

This image illustrates a mechanical pump system. It’s operated by a piston type accelerator pump. It uses one spring (delayer spring) that is placed ‘above’ the pump around the pump shaft. This spring pushes the pump down while the pump lever is held in the up position by the pump rod which is connected to a throttle lever.

The reservoir (pump bore) below the piston is filled with fuel through the inlet check. It is ready to spray gasoline into the air horn as soon as the throttle valve is opened.

As the throttle valve opens, the throttle connector rod releases the upward pressure on the accelerator pump rod, allowing the pump piston spring to force the piston down. This closes the inlet check ball and forces gasoline past the dischrage check, though the pump jet and into the air horn. When the throttle is closed, the connector rod will raise the piston and refill the reservoir through the inlet check.

Many carburetors also use a ‘return spring’ which resides in the pump bore under the accelerator pump.