The 4300 secondary’s are hooked mechanically to the primaries and open when the primaries are 3/4 open.

Each of the secondary venturi has an offset air valve plate located below its booster venturi. These plates ae preloaded by a spiral torsion spring, which holds them closed when the secondary throttles are closed.

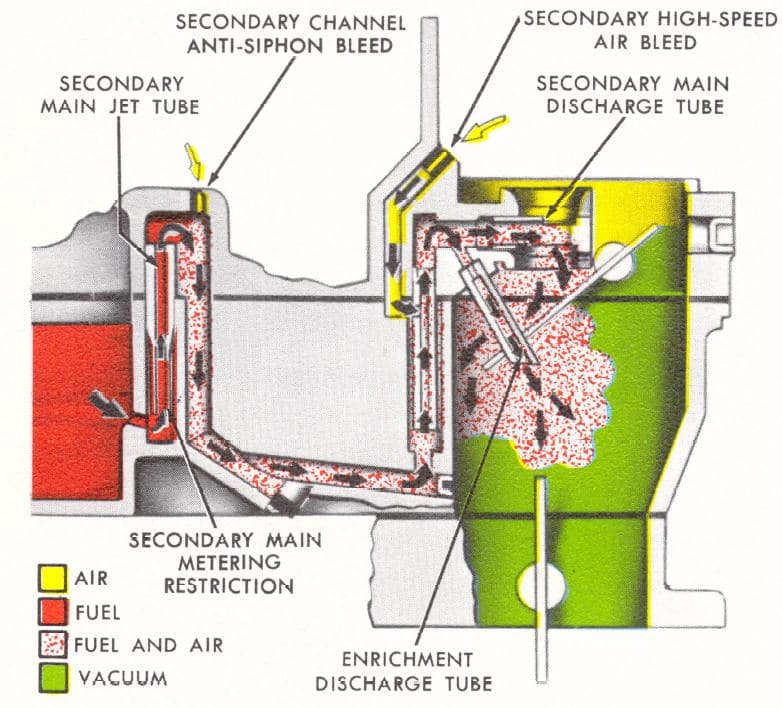

The air valve plates being closed, cause a vacuum as soon as the throttles begin to open. The fuel bowl is at air horn pressure. The pressure difference starts fuel flowing from the bowl, through the secondary main jet tube to the secondary main wells; then through the main well tubes and out the enrichment dischagre tubes.

A second stage of fuel supply occurs when the air valve plates are pulled open by manifold vacuum below them. Increased air flow then causes fuel to be discharged into the booster venturis from the secondary main discharge tubes.

The amount that the air valves open, and therefore the amount of mixture delivered, is controlled by the difference in air pressure acting on the plates balanced against the spiral torsion spring. An integral hydraulic dashpot dampens sudden movements of the plates to prevent flutter and erratic engine operations.