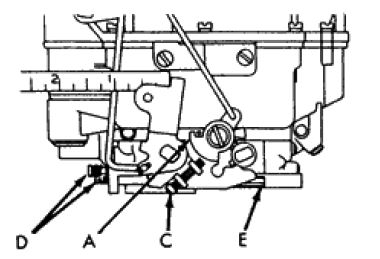

Metering Rod Adjustment

- Back out throttle screw so that the throttle valve close completly.

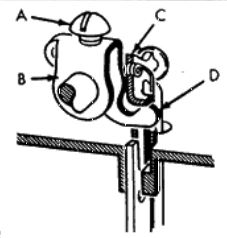

- Loosen the clamp screw A

- Press down on vacuum piston link C until metering rods bottom in the carburetor body.

- While holding the parts as indicated above, rotate the metering rod arm B until the finger on the arm at D contacts the lug on the vacuum piston link C.

- Tighten screw A and recheck.

Float Level

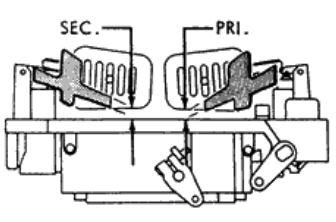

- Primary & secondary float will probably have different measurements.

- Refer to the WCFB specifications

- Hold air horn upside down with floats in place and gasket removed.

- Measure float height as illustrated above.

- Adjust by bending float arms, making sure both pontoons on each float are the same height.

- Make sure the pontoons are centered and will not rub the bowl sides.

- DO NOT apply any pressure on the needle. The carburetor will flood.

Float Drop

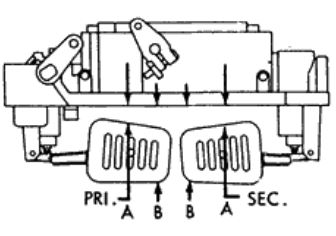

Which type do you have A, or B?

Type A:

- Hold air horn upright with floats hanging.

- Measure from center top surface of pontoons to air horn. Gasket removed as shown A.

Type B:

- Hold air horn upright with floats hanging.

- Measure from toe B to air horn. Gasket removed.

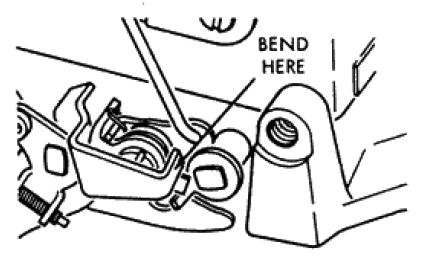

Accelerator Pump Adjustment

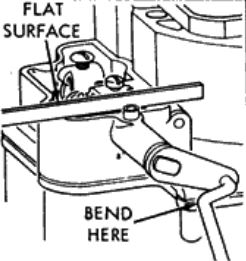

- Back out throttle stop screw until throttle valves seat in bores.

- Hold a straight edge across top of dust cover housing, next to the pump arm.

- The flat surface of the pump arm should be parallel to the straight edge.

- Adjust by bending throttle connector rod at deepest angle as shown.

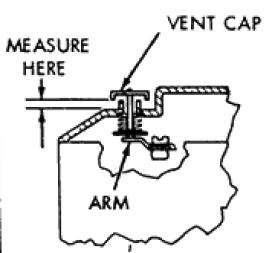

Bowl Vent Adjustment

The bowl vent is used to vent the float bowl, otherwise a siphoning of the gas can occur.

- Carburetors equipped with an adjustable bowl vent require adjustment.

- With throttle valves seated in bores, dust cover and gasket in place.

- The lower edge of vent valve cap should be raised above surface of dust cover the distance listed in the adjustment data sheet.

- If adjustment is required, remove dust cover and bend arm that operates the vent mechanism.

- Install dust cover and recheck.

Fast Idle Adjustment

Adjustment A

- Loosen clamp screw on choke lever.

- Insert feeler gauge (see adjustment data sheet) between the lip of fast idle cam and the boss on the flange casting (at A).

- With choke valve held tightly closed, take slack out of linkage and tighten clamp screw on choke lever.

Adjustment B

- With choke valve held closed and fast idle adjusting screw C, or fast idle adjusting tang, on high step of cam.

- Rotate screw C, or bend tang, until throttle valves are open the distance listed in adjustment data between throttle valves and carburetor bore, on side opposite idle adjusting screws.

Unloader Adjustment

- With throttle valves held wide open, there should be a clearance between upper edge of choke valve and the inner wall of air horn (as listed in data sheet)

- Adjust by bending unloader lip on throttle shaft lever.

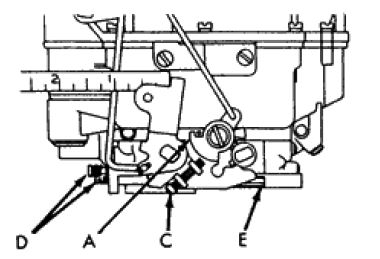

Idle Adjustment

- With carburetor installed and engine warmed up.

- Rotate throttle stop screw E until engine idle at approx 500 RPM.

- Adjust idle screws D to produce a smooth idle of correct speed is obtained.

With choke valve tightly closed, tighten fast idle adjusting screw (K) (on high step of cam) until there is the clearance as listed on carburetor specification page between throttle valve and bore of carburetor, side opposite idle port.