The Marvel-Schebler Model DLTX carburetor is a horizontal type carburetor used on John Deere tractors. To meet the specific engine requirements of the individual tractor on which the carburetor is installed requires different size jets, nozzles, venturii, throttle and choke operating levers, etc.

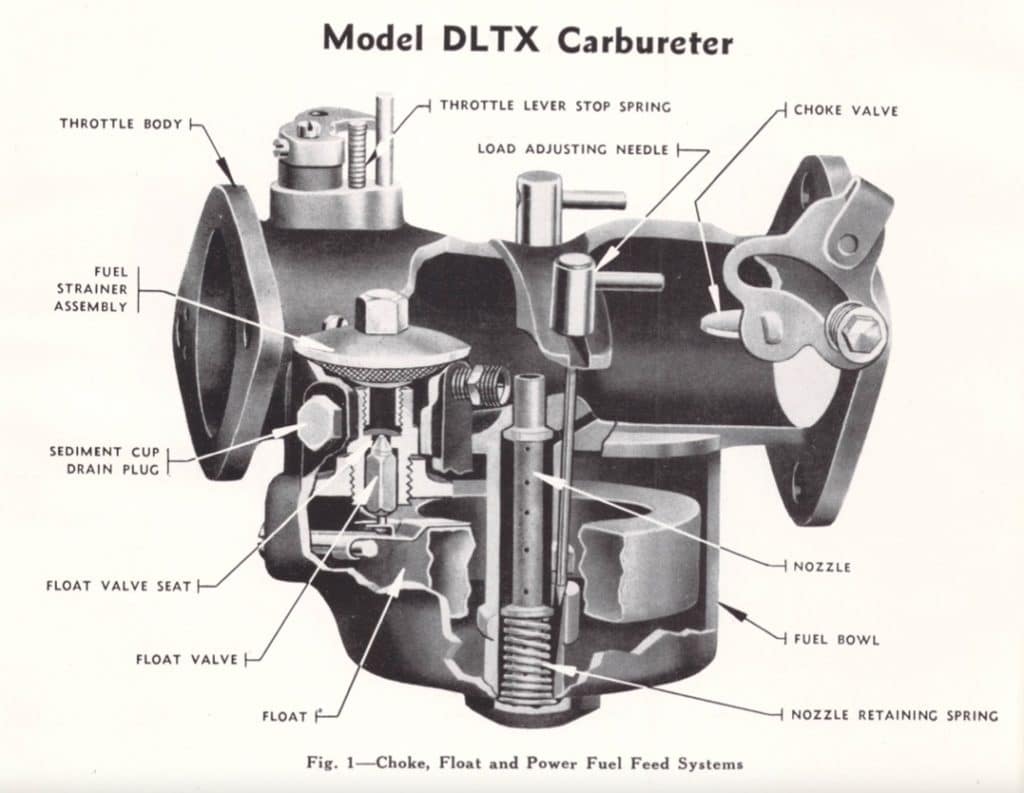

The DLTX carb consists of two main parts: the throttle body casting which contains the air inlet, and the fuel bowl casting.

The throttle body casting contains, in addition to the throttle assembly, a venturi machined in the casting and the choke assembly. Cast iron material is used for ruggedness. All passages, whenever possible, are drilled within the casting to prevent any fuel leaks to the outside of the carburetor because of shrunken gaskets or defective hole plugs.

The DLTX is completely sealed against dust or dirt. All air entering the fuel bowl of the carburetor must first pass through the air cleaner. The throttle shaft bearings and the choke shaft bearings are seal to eliminate dust and dirt entering at these points. New throttle shaft bushings can be installed when the bearings have become worn.

The float mechanism is contained in a cast iron fuel bowl on all DLTX models with the exception of the DLTX-26 and DLTX-46. In these two carburetors the float assembly is retained by the throttle body casting surrounded by a stamped metal fuel bowl.

All models have a fuel strainer to prevent dirt and foreign substance from entering the fuel bowl. To service the fuel strainer in the cast iron fuel bowl, first remove the sediment cup drain plug to permit any dirt to drain off. Then remove the fuel strainer assembly and clean with gasoline and air under pressure. Flush sidement cup by turning on fuel supply valve using a small brush to wash out any remaining dirt in the cup. Be careful not to damage or remove composition gasket on fuel strainer assembly. Always replace any damaged gasket.

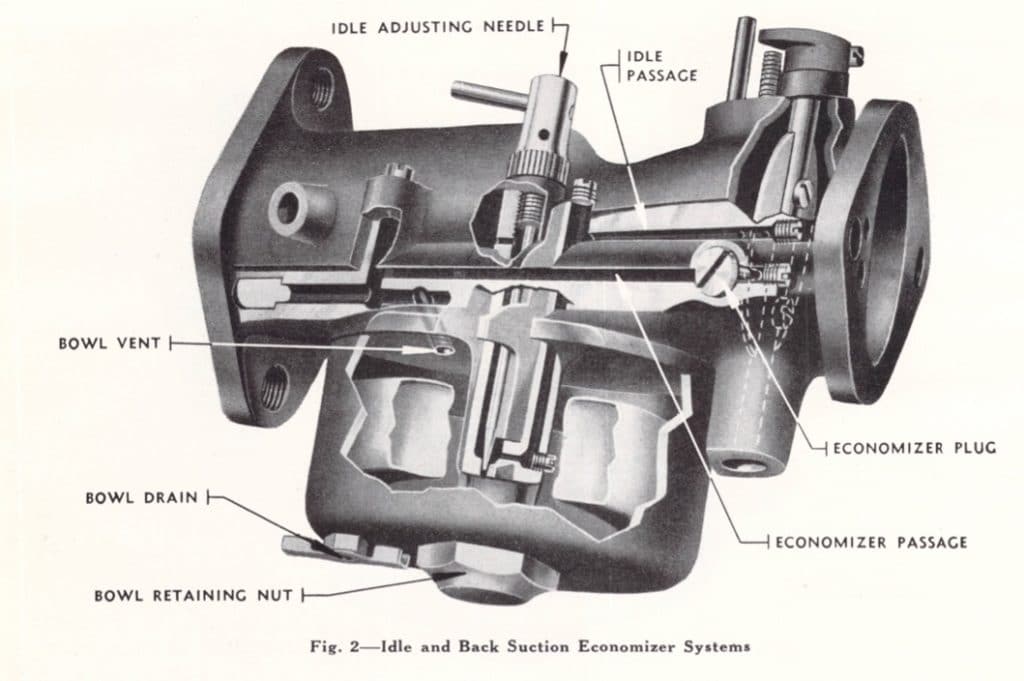

A calibrated economizer plug is used in the back suction economizer system to regulate the air pressure in the fuel bowl chamber for proper fuel delivery to the engine. The size of the plug is carefully established by engineering tests and the specified size for a given carburetor model must always be used to assure the proper operation of the carburetor on the engine. In some models, a calibrated fixed orifice is machined in the throttle body casting in place of the economizer plug.

To provide additional economy, the carburetor provides for two adjusting needles, the low speed or idle adjusting needle and the load adjusting needle. These needles must not be interchanged. The idle adjusting needle head is brass plated and the load needle cadmium plated to distinguish.

A throttel lever stop spring is provided to prevent uneven running or “hunting” (governor opening and closing) when the load is released and the governor closes clear shut. Turn the throttle stop screw against the throttle lever stop spring until the “hunting” is corrected and idling is satisfactory. Normally there is 1/32″ clearance between the throttle stop screw and the throttle lever stop spring at fast idle.

While there are many variations produced by combining the types and sizes into a specific application, all Model DLTX carbs incorporate the same engineering principles and are alike from a functional standpoint.