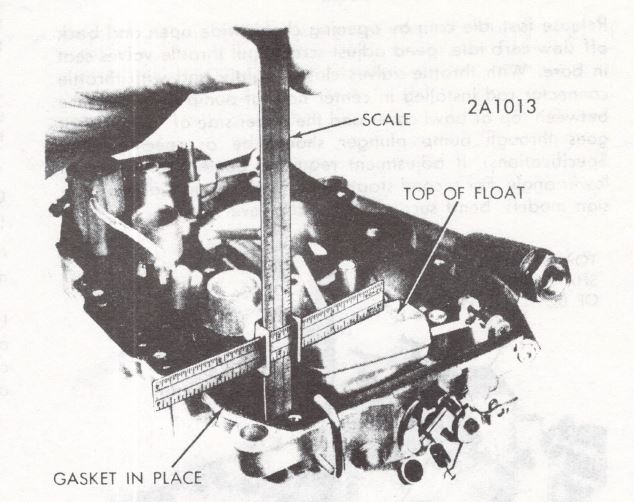

How To Adjust the Float

With bowl cover inverted, gasket installed, and floats resting on the seated needle, measure distance from bowl cover gasket to bottom of float. If measurement is not correct (see specifications), bend float as required. Do not allow lip of float to press on needle while making adjustments. This is a sure way to cause carburetor flooding.

Nitropyhl floats should weight close to 8.0 grams.

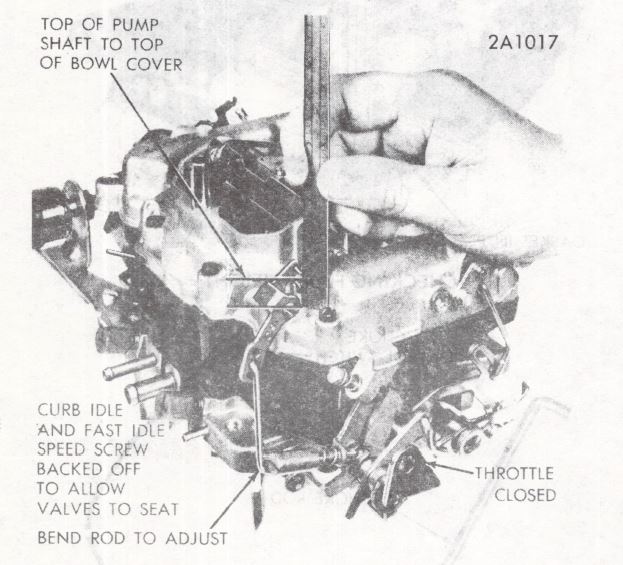

Accelerator Pump Stroke

Release fast idle cam by opening choke wide open and back off slow curb idle speed adjust screw until throttle valves seat in bore. With throttle valves closed tightly and with throttle connector rod installed in center hole of pump arm, distance between top of bowl cover and the under side of ‘S’ link that goes through pump plunger should be as specified. See specifications. If adjustment is required, bend throttle rod at lower angle. For second stage adjustment on manual transmission models, bend second stage stop lever.

Release fast idle cam by opening choke wide open and back off slow curb idle speed adjust screw until throttle valves seat in bore. With throttle valves closed tightly and with throttle connector rod installed in center hole of pump arm, distance between top of bowl cover and the under side of ‘S’ link that goes through pump plunger should be as specified. See specifications. If adjustment is required, bend throttle rod at lower angle. For second stage adjustment on manual transmission models, bend second stage stop lever.

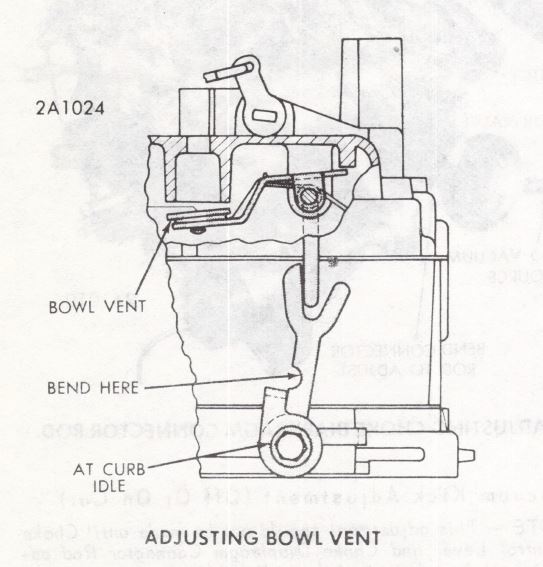

How To Adjust Bowl Vent

Remove vent valve hole plug and insert a narrow ruler in hole to rest on top of valve. Measurement of distance from top of valve to top of bowl cover should be to specifications when throttle valves are at curb idle position. If adjustment required, bend bowl vent operating lever at point of notch on lever.