Is there a washer of some kind in the bottom of the accelerator pump well?

Yes, it is used to seal the brass accelerator pump tube at the bottom of the well.

We recommend not removing the fiber washer. It is very hard to repair.

Here is a possible solution if you do take it out.

What I do to ensure sealing is to bead-blast around the bottom of the brass pump cylinder where it joins the iron casting as best I can. I then take some Permatex Threadlocker Green (it is designed to seep in between any tolerance-fit objects); I use just enough that it runs all the way around the outside of the bottom of the pump cylinder. Then I heat it using a Map/Pro gas torch to flash-cure the Permatex, and presto: no more leaks.

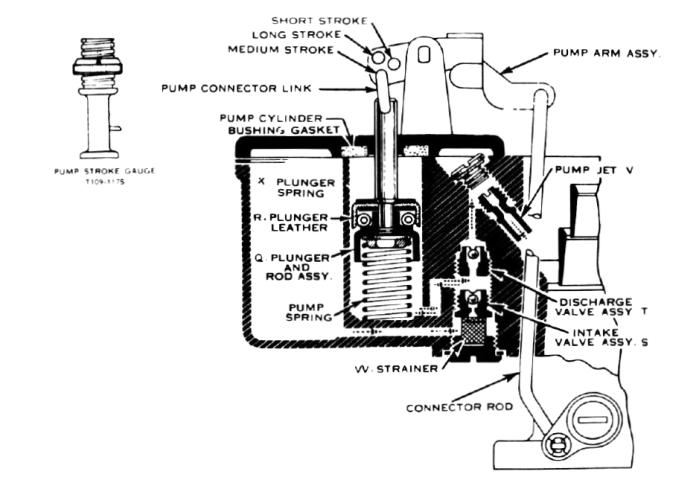

The Pump Circuit consists of the Pump Cylinder, Pump Arm Assembly ,Connector Link, Pump Plunger and Rod Assembly (Q), Plunger Leather (R), Plunger Spring (X), Intake Valve (S), Discharge Valve (T), Pump Strainer Screen (W), Pump Disc Check Valve (U), Pump Jet (V), Connector Rod, and Pump Spring.

When the Pump Plunger and Leather are first installed in the Pump Cylinder, a small amount of air is trapped between the piston and the top of the liquid gasoline. As the Accelerator Pedal is depressed, the Pump Piunger and Leather are forced downward.

This compresses the trapped air, forces the gasoline to leave the cylinder, closes the inlet valve (S), opens the discharge valve (T), closes the disc check valve (U), and discharges gasoline into the throat of the carburetor at V.

The discharge is prolonged since the hole in the tip of the pump jet is small enough to restrict the flow of fuel so long as it is being forced out by the pump travel plus the expending of the trapped air. The prolonging of the pump discharge gives the gasoline in the High Speed System sufficient time to flow fast enough to satisfy the demands of the engine.

As the accelerator pedal is allowed to return to its original position, the accelerating pump plunger is lifted upward by the link. This creates a partial

vacuum in the pump cylinder, which opens the inlet_ valve (S), closes the discharge valve (T), and draws in a charge of gasoline.

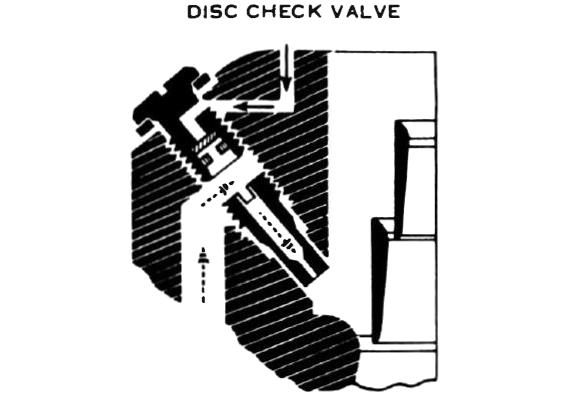

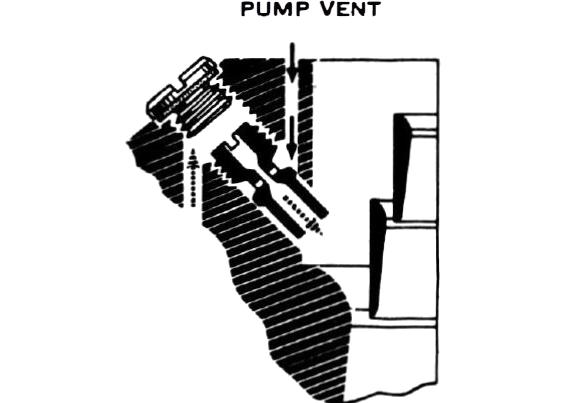

Since the discharge valve is below the liquid level of the carburetor, gasoline would be drawn into the throat of the carburetor through the pump jet from the acceleration system during fixed throttle intermediate speeds and high speeds, if it were not for the pump disc check valve (U) or air bleed to the outside, as shown on right side of cut No. 4, which breaks the vacuum of the acceleration system by bleeding in air from the float bowl.

Pump Jets are made in three types. The one above is not vented and the carburetor is calibrated accordingly.

The one illustrated at the left is vented by means of a disc check valve.

The one· at the right has a direct vent to the outside air.