THE IDLE MIXTURE SCREWS ARE A DIFFERENT LENGTH

Both screws should be the same length. Motorcraft didn’t use 2 different sized screws in any carburetor. If the screws go in at different depths in order to get the idle to smooth out and there is more than 1/2 turn difference, then there is something wrong on one side of the carburetor.

Update – Solution to this problem was a dirt. Cleaned out and all was well.

MOTORCRAFT 2150 ACCELERATION PROBLEM

You press on the gas pedal and the engine seems to bog down. What to do?

1st let me say that there are issues besides the carburetor that can make this happen, but since I’m in the carburetor business, I will assume everything else has been taken care of and concentrate on the carburetor. Also I will assume the carburetor has been rebuilt. If not, then that is where I would start.

Most likely this problem lies in the accelerator circuit. Here are some things to look for.

- Make sure the return spring is between the accelerator pump diaphragm and the carburetor body.

- Is the red umbrella check valve installed and the big end is on the pump diaphragm side?

- Check the check weight in the main discharge. This is the middle hole under the venturi cluster. The check ball goes 1st, then the check weight. You can check the check ball to see if is is sealing by holding the check ball down (use a brass drift punch), and operating the throttle. You should feel some pressure because holding down the check ball is sealing the main discharge. If you suspect the ball isn’t sealing, then use a brass drift punch to tap on the ball a few times, which will help form the hole around the check ball.

- Be sure the middle screw has a gasket.

- Using thin wire, run through all of the small holes and passage ways. Ethanol will leave deposits behind that normal cleaning will not get out. Pay special attention to the venturi cluster. There are some very small passageways in this assembly and it is very common for them to get plugged up.

- Incorrect accelerator pump adjustment. If stroke is too short, hesitation or backfire could result. If stroke is too ling, slugging, or stumble on acceleration could result.

After all of this is done add some mineral spirits to the float bowl and operate the accelerator pump. You should see fluid come up through the main discharge (where the check ball and weight is). Replace the venturi cluster and operate the pump again. You should get a fairly strong stream of fluid out of both sides of the venturi.

Do all as mentioned here and you should be able to eliminate your hesitation problem, or at least eliminate the accelerator pump circuit as the cause.

I have a tech question, if you can help. I have a Motorcraft 2150 carb and noticed that one of the idle mixture screws is longer than the other. Is this correct or should they both be the same? In fact, I order two from you and one seems to go in further than the other. Is this correct? Thanks for your help.

Both screws should be the same length. Motorcraft didn’t use 2 different sized screws in any carburetor. If the screws go in at different depths in order to get the idle to smooth out and there is more than 1/2 turn difference, then there is something wrong on one side of the carburetor.

Update – Solution to this problem was a dirt. Cleaned out and all was well.

2100, 2150 Differences

Cleanout PlugsPart 85-50

Check Weight Update: We now have the check weights available, click here to purchase. Please note this does not work on every 2150. Some use a spring.

Accelerator Pump Diaphragm Relief Hole

The hole at the bottom of the pump diaphragm cover is a relief hole. Any fuel coming out of this hole indicates the diaphragm is bad and should be replaced.

The other hole just below the pump diaphragm is a relief hole for the power valve. Any fuel coming out of this hole indicates the power valve is leaking. Not all 2150 carburetors have this hole.

Notice the deep cover over the power valve. This indicates this carburetor has a 2 stage power valve.

Q: I rebuilt my 2150 with your recommended kit. Now the vehicle run on a second or two after turning off the key. Any suggestions as to what could be causing that? I’ve changed nothing else, just the carb rebuild.

A:I think it’s running too rich.Check the needle for any damage to the viton tip. Any pressure put on the tip when installing will damage the needle.Check the bottom of the float bowl for any dirt. Dirty gas tanks, lines, or fuel filter can re introduce dirt into the carburetor causing the needle to not seal.Gently hold the float up to close the needle and suck on the fuel inlet hole. It should not allow air to pass through.Last but not least check the float level.Also does the carburetor have an idle solenoid. It may need to be not closing the throttle fast enough.

GAS IS ACCUMULATING IN THE INTAKE MANIFOLD

One possible cause for this is the main discharge might be leaking. The main discharge has a check ball that seals the discharge hole until accelerating.

To test:

Run the engine.

Turn the engine off.

Look down the carburetor throat to see if gas is trickling down the bore. It should not be.

If you see gas then the check is probably leaking. Tap the check ball gently so that it forms a bed for the check ball.

The accelerator pump circuit can be tested by filling the float bowl with mineral spirits, then pump the gas while holding down the check ball inside the main discharge. Gas should not be coming out of the discharge.

CHOKE VALVE OPEN HALF WAY WHEN CRANKING ENGINE

Make sure the thermostat is adjusted.

Do all choke circuit adjustments.

ADJUSTING IDLE MIXTURE SCREWS ALL THE WAY DOESN’T CHANGE ANYTHING

Here are some possibilities:

- Vacuum leak – Check around the mounting gasket, Ends of throttle shafts in case they are wrong and leaking vacuum. Check intake gasket and any hose connection that leads to vacuum.

- The idle passage could be plugged. Remove the idle mixture screw and blow through the passage. Feel the top of the venturi to see if the air is coming through. You may have to tape off the idle mixture hole inside the bore so air will go directly up through the carburetor.

- Your carburetor may be running very rich, or flooding. Do you get a gas smell, or black smoke out the tailpipe? Look for the flooding section for a list of possibilities.

- Try covering the carburetor bore with the engine running until it almost dies. The vacuum created will sometimes unclog a passage.

WON’T RUN WITH CHOKE OPEN

This is caused by either a vacuum leak, or a very lean condition. Here are some possible reasons, not in any order.

- Fuel line kinked

- Rubber fuel line collapsed – Be sure you are using fuel injection hose. Ethanol will eat the old type hose.

- Fuel pump weak – test for 4.5 – 5 lbs. Refer to your motors manual for exact specification. A volume test may also be necessary.

- Has the car been sitting for months? Gas may have turned and varnished the inside of the carburetor. Passages may be plugged. Simply replacing the gas will not work. Gas tank and fuel lines will be varnished. You may smell the varnish.

- Dirty carburetor.

- Change the fuel filter.

- Float not dropping to open float valve.

- Check for vacuum leaks around mounting, vacuum lines & intake.

- Throttle shaft worn. Spray carb cleaner around ends of throttle shaft. If RPM changes, you have a vacuum leak.

RUNS RICH, OR BLACK SMOKE OUT OF TAILPIPE

- Ignition not up to par. Don’t be too quick to blame the carburetor. Ignition problems are more likely.

- Did you get a carburetor at sea level, then move it to 5,000 feet plus? The jets will need to be reduced by .002. Current jet size will be stamped on jets. 50F=.050

- Look down the carburetor at idle, or right after turning off the engine. Is gas dribbling out of the venturi. If yes, then you have a siphon problem which is usually caused by the main discharge leaking.

- Check that the venturi gasket is flat. They sometimes need to be trimmed.

- Is the check ball leaking? Tap the ball gently to form a good seal.

- Is there something above the check ball to hold it closed. Some 2150 carburetors use a check weight and some use a spring. It takes very little to hold the check ball down.

- Check the float level. Set to specifications. Don’t fudge it. You will be covering up some other problem.

- Look at list under FLOODING below.

FLOODING

Gas is over flowing somewhere over the top, or perhaps gas is running out of the throttle shaft.

- Top suspect would be the float valve, or needle & seat. With float up (closing needle), blow into the fuel inlet. The needle should stop the fuel. Over 5 lbs will open the needle. Keep that in mind. A 150 lb air compressor will open the needle.

- Fuel pump pressure is too high. Check motors manual for specification but around 4.5-5 lbs. would be good.

- Float is too heavy. Nitrophyl float may have absorbed fuel, or brass float may be leaking.

- Float is catching due to a worn, or bent float pin.

- Float is so mal adjusted that it is letting in too much fuel.

GOING AROUND CORNER, OR COMING TO A STOP KILLS THE ENGINE

- Wrong float bowl gasket may be allowing fuel to flow over the bowl into the engine.

- Warped float bowl, or float bowl top may be allowing fuel to flow over the bowl into the engine.

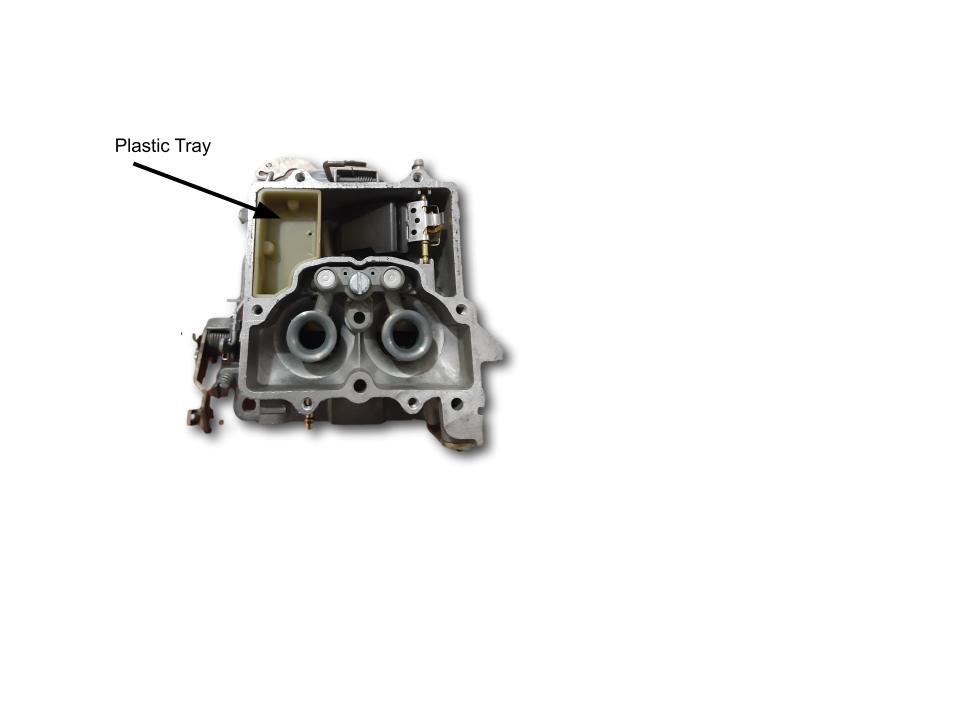

New Float Doesn’t Fit

When changing from a Nitrophyl float to a brass float and the float bowl has a over fueling plastic tray, remove the tray. The benefits of using the brass float outweighs the benefit of the tray.

Starts Up, High Idle, then Dies

- Could be a vacuum leak – check around the base of the carburetor, all vacuum lines and the intake manifold.

- Before starting cold open the throttle a bit to allow the fast idle to be set. The choke valve should be closed and the idle screw on the high spot of the fast idle cam.

- After the engine starts and it is still cold does the choke valve stay closed (or almost closed)? If not, then you need to look at the choke adjustments.

- If the choke is working as it should, then look at gas restriction (not enough gas).

- Fuel filter plugged.

- Gas line kinked.

- Old rubber type of fuel line could be collapsed inside from ethanol. Use fuel injection hose.

- Needle & seat sticking – Remove the top and view the action of the needle when the float is moved up and down. Be sure the float is connected to the needle and that it is pulling the needle out straight. That is how it is pulled out.

- Test the fuel pump for 4.5 lbs of pressure (check motors manual for exact measurement).

Idles Too Fast Even With Choke Open

- Turn idle screw out (counter clockwise). Does that idle it down?

- Disconnect throttle linkage to make sure it isn’t holding the throttle valves open.

- Throttle valves were installed incorrectly. Do you see light around the throttle valves?

- Corrosion or carbon is holding the valves open.

- A vacuum leak can make the engine idle too fast. Spray carb cleaner around the mounting, intake manifold and all vacuum lines. If the idle smooths out and slows down then you found the problem.