Rochester 2 Jet Tri Power

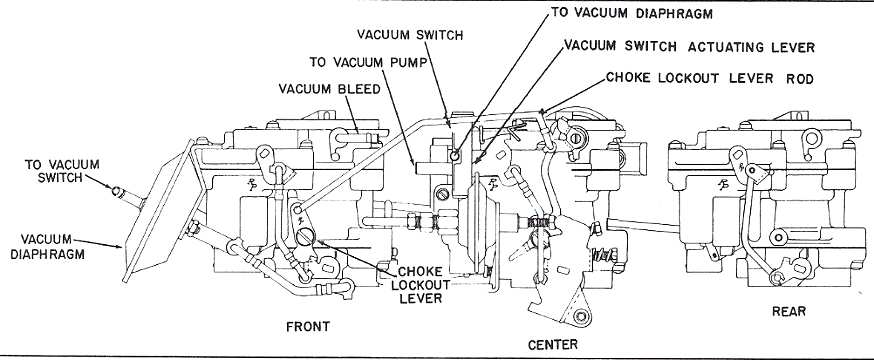

Rochester Tri-Power carburetor kits. These are the 2G and 2GC carburetors. The 2GC is the carburetor in the middle and would have the automatic choke attached. The front and rear carburetor does not have a choke. The outer carburetors also don’t have idle mixture screws. The center carburetor is used for the idle & low speed circuit. The outer carburetors are used to kick in when powering up.

The outer carburetors should have the idle mixture blocked off if not original tri-power carburetor. The power piston & power jet should also be blocked off.

If you are using non-standard 2 jets, then you will need to modify the outer carburetors in order to get a good running tri-power. The outer carburetors should be exactly the same.

Selecting kits for the tri-power carburetors is straight forward if you still have the tags attached to the top of the carburetor. Rochester did not stamp the carburetor number in the side of the carburetor until 1968.

Tri-power carburetors use two different carburetor kits. One kit for the center and the other kit for the front and back carburetors. Each kit services one carburetor, so to do all three carburetors you will need three kits. 1958 Oldsmobile tri-power used the same kit for all 3 carburetors. The center carburetor 7011973 and end carburetors 7011714 (rear), 7011712 (front).

Be careful because chances are you may not have the original carburetors. It is rare that we see a tri-power setup that has the correct carburetors (numbers matching).

Here is an example of a tri-power setup. Notice that the front an rear carburetors use the same carburetor kit, but the center carburetor uses a different kit.

1959-61 Chevrolet V-8 A/T NO AIR

| 7013015 FRONT CARBURETOR | K6121 | |

| 7013017 REAR CARBURETOR | K6121 | |

| 7013016 CENTER CARBURETOR | K636 |

What if you don’t have the carburetor tags?

You have to make the best guess and the suggested way is to take the carburetor apart and carefully compare the old parts with the parts we have illustrated in the photos, or videos.

Here are the typical carburetor kits used on the Chevrolet carburetors (prior to 1968)

K636

K355

K427

K6121

Jet size: Center Carburetor .055, Outer Carburetor .052

When running a progressive linkage on a tri-power setup the two end carburetor act like drones.. Must remember, that if he is using two regular carbs (non tri-power) as drones you must shut down the idle circuit on both. The drones must not add any fuel or air when they are not in use!!! That means you back of the idle screw so the throttle plates are totally closed when not being used. You also shut down the idle circuit (turn both air fuel mix screws in tight). you run off the main carburetor until you reach the 55/60% of throttle then the drones come into play. They add fuel & air, after the pump squirt. Sometimes they eliminate the power valve function on the drones (too much fuel), but they should work with the power valve function (2G p/valves open between 6 & 8 hg .

1958 Chevrolet Tri-Power Setup

1958 Oldsmobile Tri-Power Set Up

1958 Chevrolet Tri-Power Setup

1958 Oldsmobile Tri-Power Set Up

1958 Pontiac Tri-Power Setup

Back Fires or Floods on Stops, or Hard Turns

This is most likely due to excess fuel being dumped into the carburetor bore.

Check the float to make sure it isn’t catching.

Test the float by immersing in hot water. Any bubbles indicates a bad float.

Double check the float level.

Check the float bowl for warpage, or a wrong float bowl gasket. Gas may be slopping over the side of the float bowl and into the bore on hard turns, or stops.

Test the fuel pump pressure. Should be under 5 lbs.

Check the needle closely for any scoring on the black viton tip. They may have been damaged when installed. Turn the top upside down and apply 4-5 lbs of air to the inlet. The needle should hold.

Make sure the outboard carburetors are not supplying extra fuel at low RPM.

Tri-power doesn’t idle, or has a rough idle.

The 1st thing to look at is the electrical system. Any number of things can cause a rough idle. Looking at the carburetors should be left for last. I’m not going into the electrical here. My main focus will be on the carburetors.

The end carburetors should not influence the idle. True tri-power end carburetors do not have an idle circuit. If you are using transplant carburetors, then you need to eliminate the idle circuit. Having an idle circuit is easy to tell. There would be 2 idle mixture screws sticking out the front.

Also the end carburetors should not have an power valve, or power piston.

Assuming the end carburetors are set up correctly focus on the center carburetor. Check the idle mixture. Adjust the 2 screws for a smooth idle. If they don’t make any difference when adjusting then you have other problems.

There are two idle passages that come out the bottom of the bore. The lower one is the idle screw passage. The one just above it is the off idle passage. The off idle passage allows a bit more air/fuel mixture to get you between idle & the accelerator circuit. Make sure both holes are clean and clear. Blow air into each hole. The air should come out of the venturi (with the top off).

Inspect the idle mixture screw for any grooves in the tapered end. If so, replace them.

Check all of the small holes in the venturi. They are small and easily get plugged.

Look around for vacuum leaks. Intake, carburetors and any vacuum line attached to the engine.

Linkage Adjustment

Disconnect the end of throttle actuating rod which connects the throttle levers on the front and rear carburetors. With both throttle valves closed on the front and rear carburetors, the rod should center in the slot in the throttle lever. Bend the throttle rod to adjust. Connect throttle rod after adjustment. Set connecting link between center & rear carburetor. Loosen lock nut. With the center carburetor manually held to wide open throttle, turn adjusting nut to give wide open throttle on rear carburetor. Tighten lock nut.

TRI-Power Adjustments