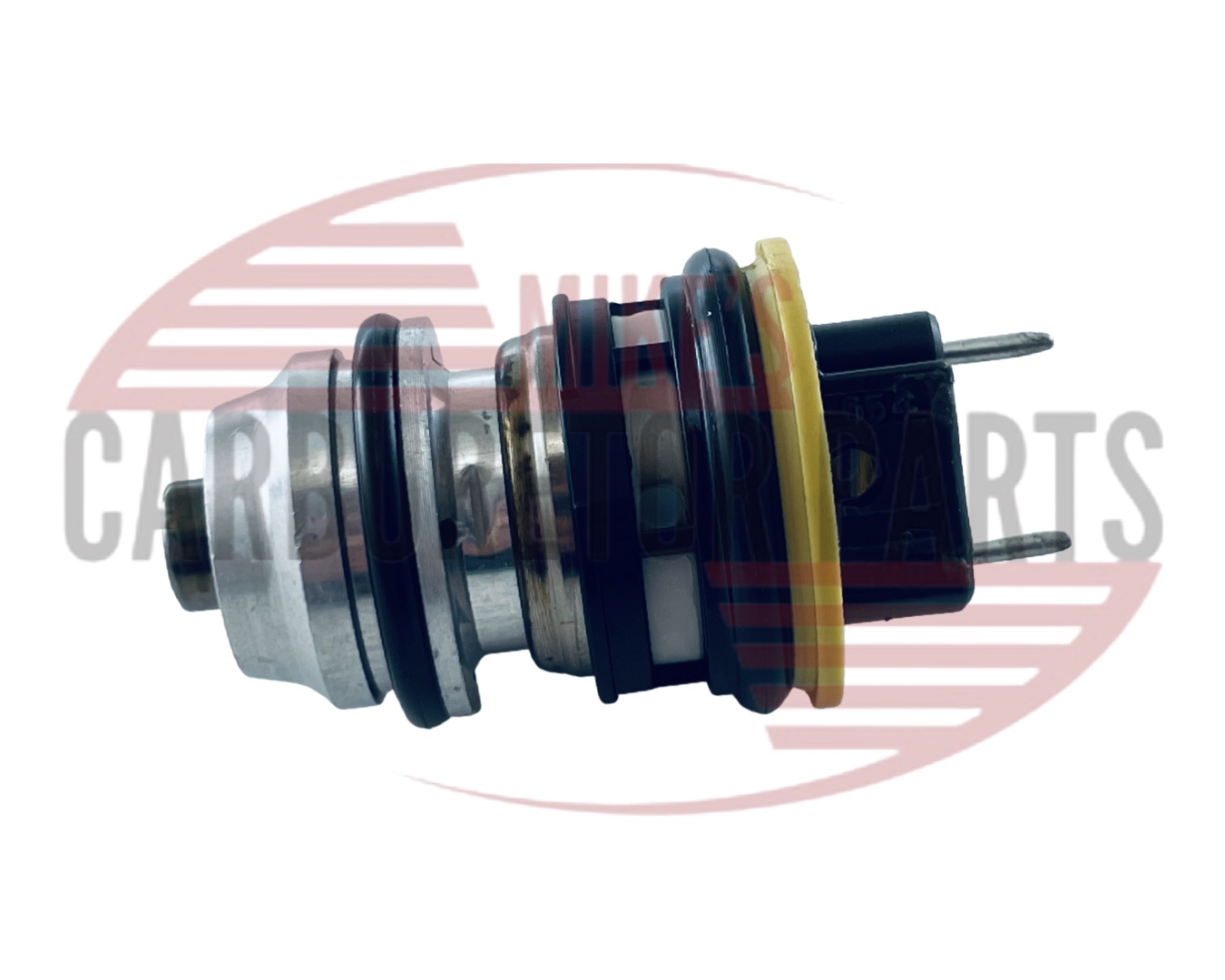

Injector Technical Support and Parts

Find your carburetor type below

Have a general question? Start here…

Brass Fittings

Complete Carburetors

Discounts, Free Shipping, Coupon Codes

Do you have a physical location?

Do you ship to (fill in the country)?

E-Manuals

Electric Choke Conversion Kits

Need a Rebuild Kit? Start Here…

Rebuilding, Rebuilders

Returns

Shipping

Technical Help

Throttle Shafts and Bushings

Wrong, Damaged, Missing Items

Complete Carburetors

Discounts, Free Shipping, Coupon Codes

Do you have a physical location?

Do you ship to (fill in the country)?

E-Manuals

Electric Choke Conversion Kits

Need a Rebuild Kit? Start Here…

Rebuilding, Rebuilders

Returns

Shipping

Technical Help

Throttle Shafts and Bushings

Wrong, Damaged, Missing Items